+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

Get a Quote

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

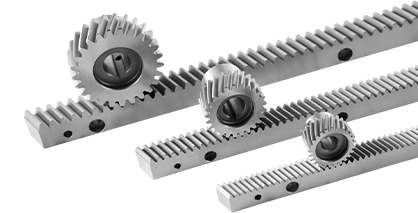

Mechanical systems often involve multiple components with varying costs. Understanding Rack And Pinion Price helps buyers forecast total project expenses. Competitive pricing supports both small-scale maintenance and large production budgets without compromising quality.

Different suppliers offer varying cost structures depending on production scale, material choice, and quality control. Comparing Rack And Pinion Price across multiple suppliers allows buyers to select reliable partners while optimizing budgets for mechanical assemblies.

Material selection directly impacts cost. Steel, alloy, and treated metals differ in durability and manufacturing complexity. Evaluating Rack And Pinion Price in relation to material ensures buyers balance performance requirements with investment limits.

CNC machining, heat treatment, and surface finishing all contribute to final Rack And Pinion Price. Buyers who understand how manufacturing methods affect cost can make informed sourcing decisions, balancing efficiency and reliability.

Load capacity, rotational precision, and wear resistance influence component pricing. Considering Rack And Pinion Price in conjunction with performance requirements helps prevent overpaying for unnecessary specifications while ensuring functionality.

Large-volume procurement often lowers unit costs. Suppliers may offer discounts based on order size, affecting the overall Rack And Pinion Price. Buyers planning multiple projects can achieve better value through bulk ordering strategies.

Reliable suppliers reduce the risk of defects, delays, and warranty claims. Evaluating Rack And Pinion Price alongside supplier performance ensures cost-effectiveness while maintaining consistent quality and delivery schedules.

High-demand periods or limited material availability can increase pricing. Monitoring trends in Rack And Pinion Price helps buyers anticipate budget fluctuations and negotiate better terms with suppliers.

Complex pinion or rack geometries require advanced manufacturing, impacting Rack And Pinion Price. Buyers must assess whether intricate designs are essential or if standard components meet system requirements.

Applications vary from automotive steering systems to industrial machinery. Evaluating Rack And Pinion Price in context of specific use cases ensures buyers align cost with operational expectations and durability needs.

Cost, quality, lead time, and after-sales support are key evaluation factors. Understanding Rack And Pinion Price alongside these criteria helps manufacturers and distributors choose suppliers that offer optimal value.

Geographical factors such as labor cost, material sourcing, and transportation impact Rack And Pinion Price. Buyers sourcing internationally must account for additional expenses to accurately assess total procurement cost.

Long-term ownership costs include maintenance and potential replacements. Assessing Rack And Pinion Price with lifecycle costs ensures that buyers do not compromise system longevity for short-term savings.

Modern production techniques can reduce labor and material waste, lowering Rack And Pinion Price over time. Keeping up with technological improvements helps buyers optimize sourcing strategies and cost efficiency.

Combining supplier comparisons, bulk ordering, and quality evaluation supports cost-effective purchasing. Considering Rack And Pinion Price alongside long-term operational benefits helps businesses make informed procurement decisions.