+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

Get a Quote

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

A Ground Gear must be manufactured from high-quality steel or alloy to endure high torque and continuous operation. Heat treatment and surface hardening increase resistance to wear and deformation. Selecting a reliable Ground Gear ensures optimal performance, extending the operational life of machinery.

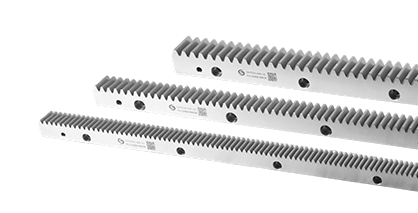

Precision grinding is critical in producing a Ground Gear. Accurate tooth profiles and alignment reduce vibration, minimize backlash, and improve motion transmission. A finely ground Ground Gear delivers smoother operation, lower noise levels, and higher energy efficiency in industrial systems.

The design of teeth in a Ground Gear affects how force is distributed during rotation. Proper geometry ensures even stress distribution, reducing localized wear and preventing premature failure. Engineers using a Ground Gear with optimized teeth achieve better performance under heavy-load conditions.

Different machinery applications require varying specifications. A Ground Gear can be customized in module, pressure angle, tooth width, and surface finish. Customized Ground Gear solutions enable integration into robotics, conveyors, and precision machinery, meeting exact operational requirements.

Proper lubrication is essential for a Ground Gear to minimize friction, heat, and wear. Using appropriate grease or oil and maintaining lubrication schedules prevents damage and enhances reliability. A well-lubricated Ground Gear ensures smooth operation and reduces the need for frequent maintenance.

Balanced load distribution across teeth increases the durability of a Ground Gear. Reinforced backings and optimized tooth spacing reduce stress points, preventing mechanical failures. Engineers relying on a properly designed Ground Gear maintain consistent performance and machine safety over time.

A Ground Gear plays a crucial role in automated systems, including assembly lines, CNC machines, and robotic arms. Accurate motion transfer ensures precise operation, reducing errors and improving throughput. Incorporating a high-quality Ground Gear enhances automation efficiency and productivity.

Every Ground Gear undergoes inspection for tooth accuracy, alignment, surface finish, and hardness. Quality control guarantees that the gear performs reliably under operational stress. A Ground Gear produced under strict standards minimizes downtime and strengthens trust in industrial systems.

Modern techniques such as CNC machining, precision grinding, and laser hardening produce a Ground Gear with exceptional accuracy and surface quality. Advanced manufacturing reduces variability, enhances durability, and ensures consistent performance in demanding industrial environments.

Scheduled inspections and preventive maintenance of a Ground Gear prevent unexpected breakdowns. Monitoring wear patterns, alignment, and lubrication levels ensures continuous operation. Effective maintenance planning allows factories to rely on a Ground Gear for extended periods without costly repairs.

Innovations in materials, coatings, and production methods enhance the efficiency and lifespan of a Ground Gear. Hybrid alloys, friction-reducing coatings, and 3D-printed components enable gears to handle higher loads and complex operations, giving manufacturers a competitive advantage.

Timely availability of Ground Gear components ensures smooth assembly and repair processes. Efficient production planning, quality packaging, and reliable shipping reduce project delays. A well-managed supply chain allows engineers to integrate Ground Gear into machinery on schedule, supporting industrial productivity.