+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

Get a Quote

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

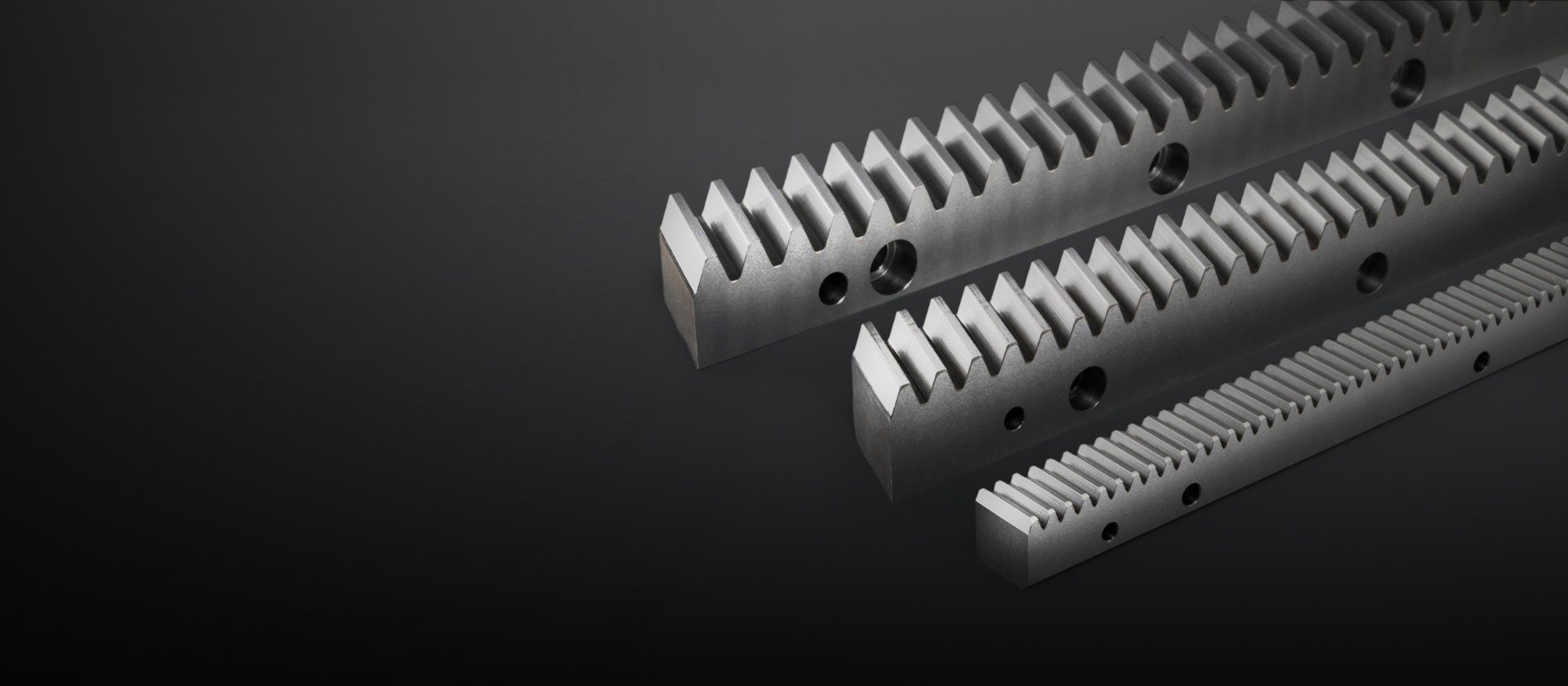

Movement inside industrial equipment often depends on coordinated mechanical interaction. A Rack And Pinion Rack Manufacturer contributes to this process by producing components that transform rotating force into guided straight-line travel.

From automated warehouses to metalworking equipment, linear systems help position materials accurately while supporting repeatable workflows. When racks engage smoothly with pinions, machines can adjust direction without unnecessary interruption.

As industries explore smarter production layouts, the demand for stable motion hardware continues to grow alongside technological adoption.

Engineering teams frequently evaluate how motion components influence operational rhythm. Working with a Rack And Pinion Rack Manufacturer allows them to match tooth geometry with performance targets such as positioning accuracy and mechanical balance.

Attention often centers on engagement consistency. Even contact between gear teeth supports controlled travel, which can benefit applications requiring measured adjustments rather than abrupt transitions.

Noise awareness has also entered design conversations. Refined tooth profiles may contribute to quieter mechanical environments, an aspect sometimes valued in facilities running multiple machines simultaneously.

Manufacturing precision often begins with digitally guided machining. Inside a Rack And Pinion Rack Manufacturer, CNC equipment typically supports repeatable cutting paths that align with detailed engineering drawings.

Secondary finishing processes can refine tooth surfaces, supporting smoother interaction once installed. Measurement tools then compare completed parts against specified tolerances, helping maintain dimensional reliability across production runs.

This layered approach reflects how modern factories combine software guidance with mechanical expertise to produce consistent transmission elements.

Material planning frequently reflects working conditions. Hardened steel attracts attention in applications involving continuous load cycles, while alloy blends may be selected for their balance between rigidity and adaptability.

A responsive Rack And Pinion Rack Manufacturer often provides multiple treatment paths, allowing buyers to select surface characteristics suited to their operational environment.

For projects where weight enters design calculations, alternative metals sometimes become part of early engineering discussions. Matching material traits with system demands helps support steady mechanical behavior.

Thermal processing alters internal metal structure, shaping how components respond during repeated engagement. Within a Rack And Pinion Rack Manufacturer, controlled heating stages can strengthen outer layers while maintaining internal resilience.

This combination supports durability during frequent motion cycles without dramatically changing the component’s geometry. Engineers commonly review treatment data to align parts with expected workload patterns.

Understanding these processes can clarify how racks may perform once integrated into active machinery.

Industrial equipment rarely follows identical blueprints, which explains the growing interest in tailored components. Collaborating with a Rack And Pinion Rack Manufacturer often allows adjustments in length, module size, mounting interfaces, or tooth configuration.

Such flexibility supports smoother integration into specialized systems, reducing the need for extensive redesign. Equipment builders sometimes value this adaptability when refining new machinery concepts.

Customization also creates opportunities for manufacturers to participate earlier in development cycles, contributing technical insight before production begins.

Quality review frequently unfolds across multiple checkpoints. Material verification, in-process measurements, and post-machining evaluations each contribute to production stability.

At a Rack And Pinion Rack Manufacturer, technicians may examine straightness, spacing accuracy, and surface condition prior to packaging. These checks help parts arrive ready for assembly with fewer unexpected adjustments.

Documentation accompanying shipments can further assist engineering teams by providing traceable measurement records.

As automated systems expand across logistics hubs and fabrication facilities, motion hardware continues attracting procurement attention. Guided travel paths often depend on reliable rack engagement to support positioning routines.