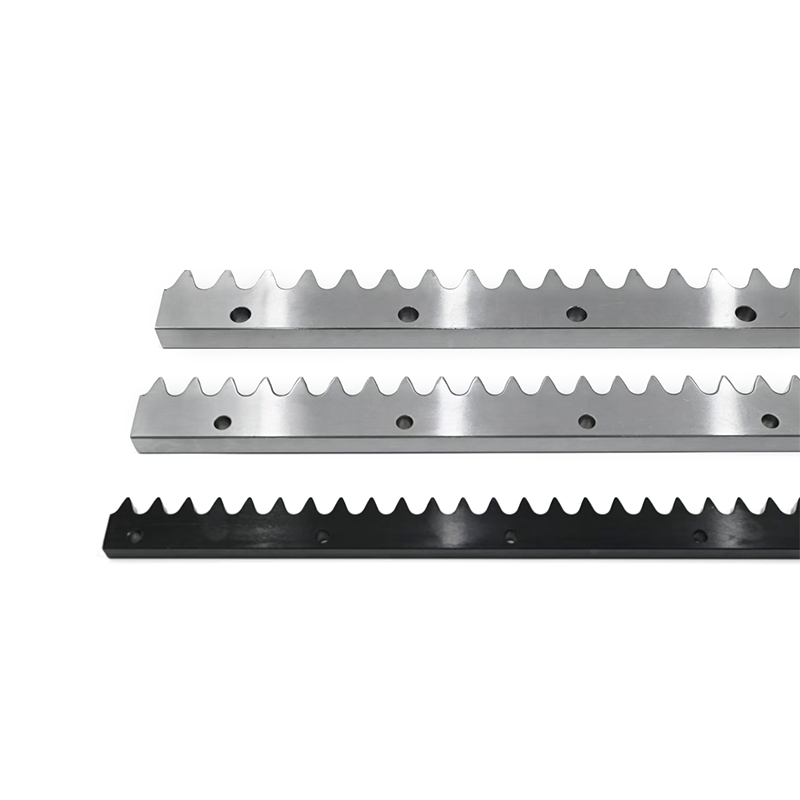

Zero Backlash Roller Rack & Pinion

Zero Backlash Cycloidal Roller Rack and Pinion

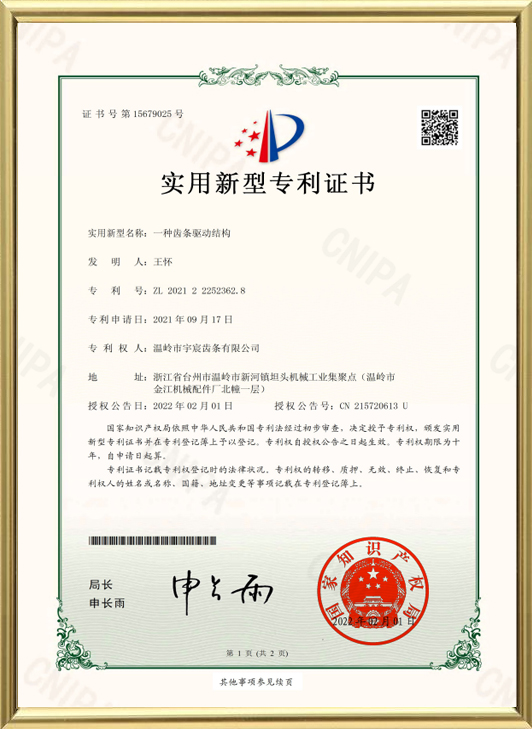

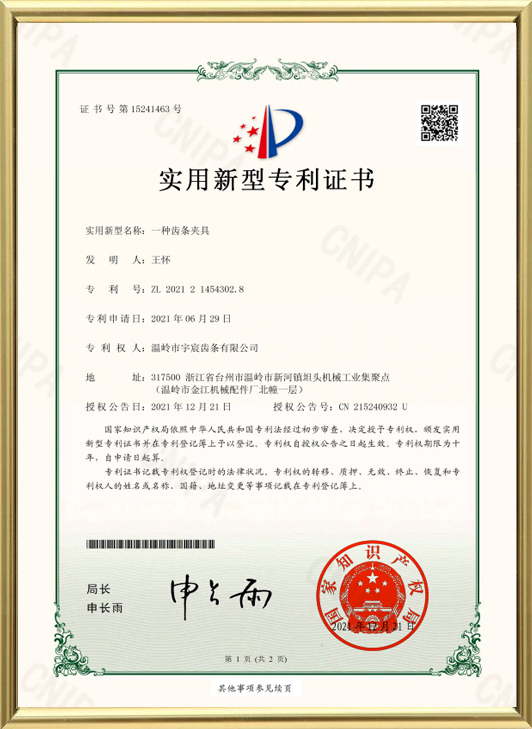

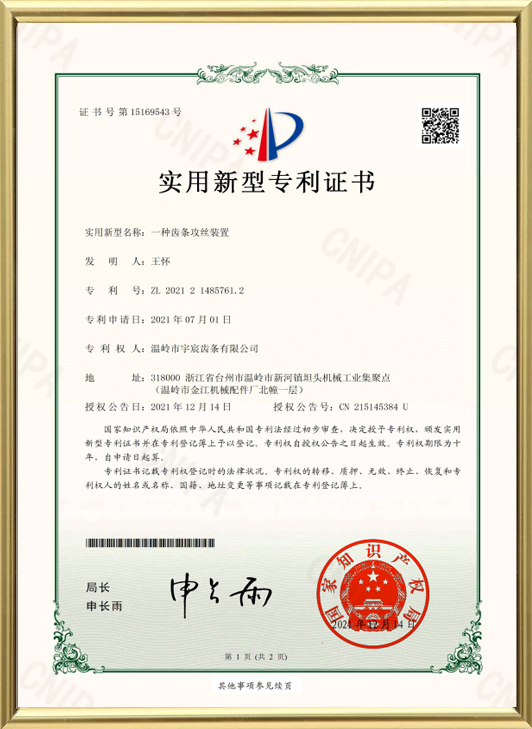

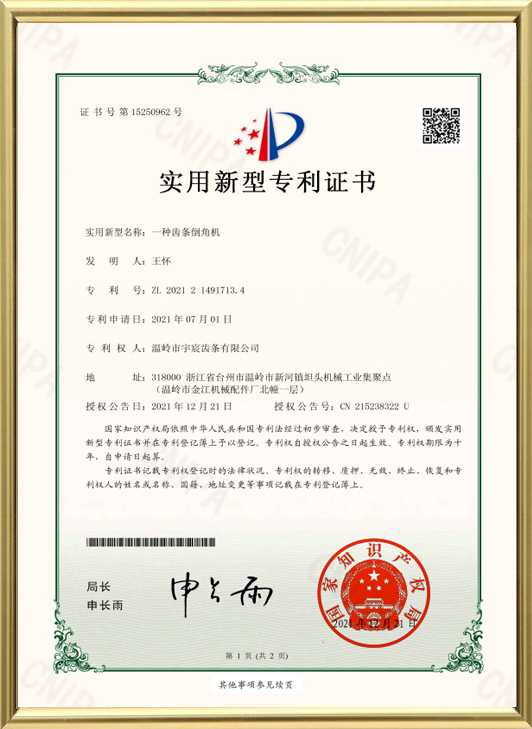

In the world of industrial motion control, even the slightest deviation can lead to costly consequences. Backlash, in particular, is a major barrier to achieving precision. The Zero Backlash Cycloidal Roller Rack and Pinion developed by Yuchen redefines accuracy in motion systems. Engineered for high-performance applications such as automation equipment and CNC machinery, it delivers a new standard in backlash-free linear transmission.

Zero Backlash Design for Unmatched Positioning Accuracy

This system features a unique engagement design in which the rollers consistently maintain 2 to 3 points of contact with the rack. This configuration eliminates clearance between the teeth in both directions, ensuring true zero backlash. With positioning accuracy reaching ±20 microns, it functions like a precise guidance system. This enables robotic arms to grasp and place components with high repeatability and allows CNC machines to execute micrometer-level machining—meeting the stringent demands of precision manufacturing.

High-Speed and Stable Motion for Enhanced Productivity

The rolling engagement mechanism significantly reduces friction, enabling linear speeds exceeding 180 meters per minute. The result is ultra-smooth operation with less noise and vibration. In automated production lines, this leads to faster material handling and higher throughput. In laser cutting systems, the cutting head moves swiftly while maintaining sharp, clean edges—contributing to improved product quality.

Low Wear and Low Particle Generation for Sensitive Environments

The smooth rolling contact between pinion and rack ensures that moving parts operate at low speed and small diameter, resulting in less wear and dust generation. This makes the system ideal for environments that demand high cleanliness, such as semiconductor fabrication and electronics manufacturing. It effectively prevents particulate contamination of sensitive components. In addition, the robust construction ensures stable performance even under harsh industrial conditions.

Easy Installation and Low Maintenance

The Yuchen Zero Backlash Cycloidal Roller Rack and Pinion is designed with user convenience in mind. Its straightforward installation process reduces labor and setup time, while its high wear resistance and stable performance minimize maintenance needs and lower the total cost of ownership. This means reduced downtime and increased peace of mind for operators.

Combining zero backlash, high precision, smooth high-speed operation, low wear, less dust generation, and easy installation, the Yuchen Zero Backlash Cycloidal Roller Rack and Pinion is a reliable and efficient transmission solution. Choosing Yuchen means embracing a more accurate, efficient, and durable power transmission system—empowering your business to stand out in a competitive industrial landscape.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español