Ground Gear

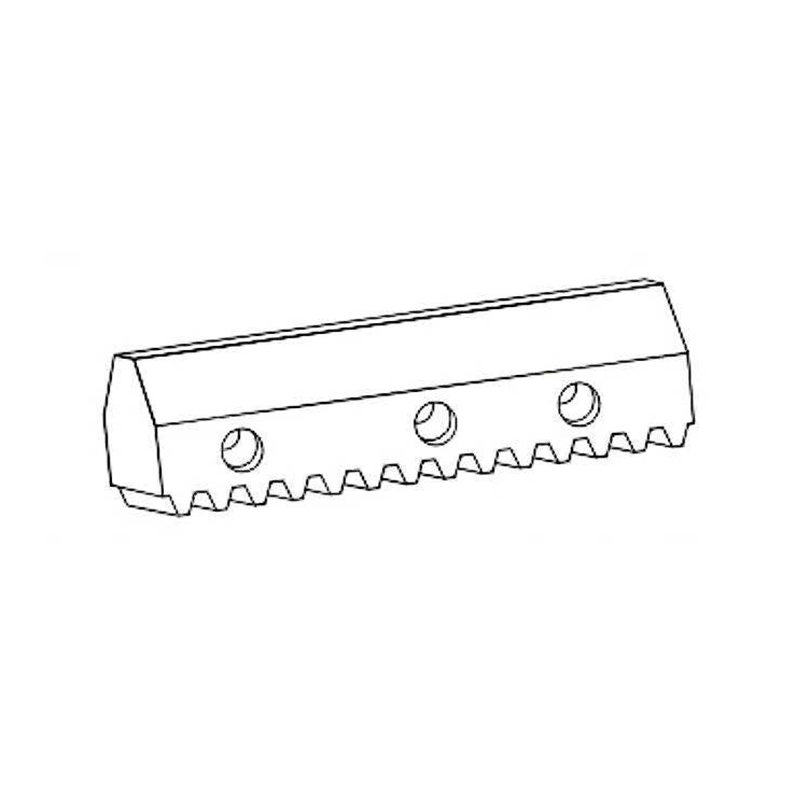

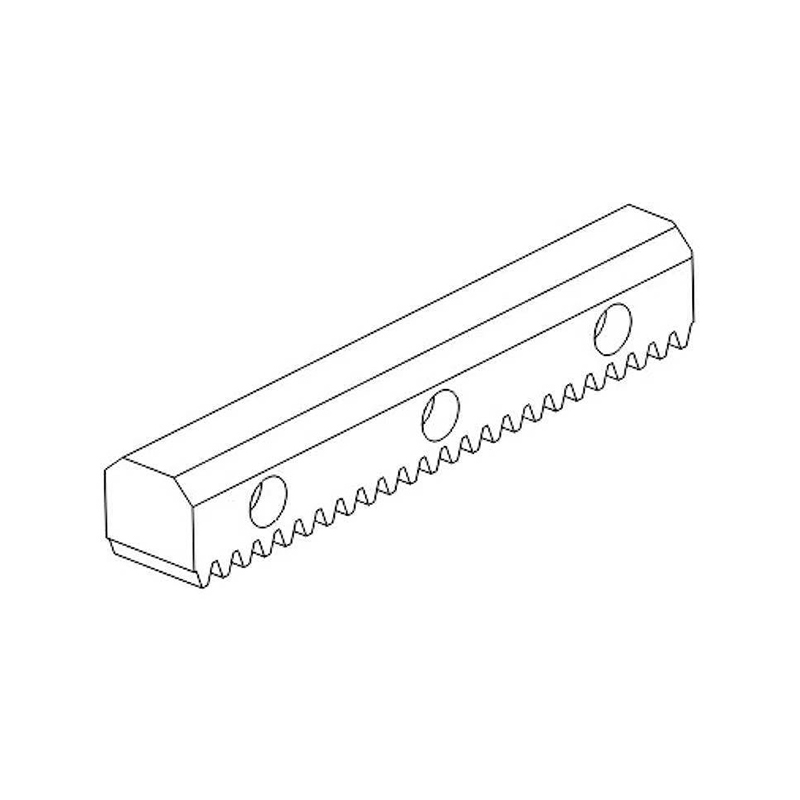

4M DIN6 Ground Helical Gear

Specifications

Precision Grade: DIN 6

Material: 20CrMnTi

Type: Helical Rack

Left hand angle: 19°31'42"

Hardness Treatment: Overall carburizing, HRC55–60

Manufacturing Process: Gear grinding

In the world of precision mechanical transmission, the synergy between Yuchen gears and racks exemplifies an ideal power solution—where the gear plays a vital and irreplaceable role.

Accurate Power Transmission – Driving the Core of Motion

The 4M DIN6 Ground Helical Gear by Yuchen acts as the key hub for power delivery. When driven by motors or other power sources, its helical tooth profile—crafted through rigorous machining and grinding processes—ensures perfect engagement with Yuchen racks. Every contact between gear and rack accurately converts rotary motion into linear motion, transmitting force smoothly and efficiently. On automated production lines, this gear rotates at high speeds to drive the rack and guide robotic arms for precise component handling, guaranteeing seamless workflow and acting as a core driver of equipment stability and efficiency.

Flexible Speed Adjustment for Varied Industrial Applications

Yuchen’s 4M DIN6 Ground Helical Gear, when paired with matching racks, enables flexible speed variation tailored to complex working conditions. By modifying parameters such as tooth count and module, and matching with different rack specifications, it can meet both heavy-load low-speed and light-load high-speed scenarios. In machine tools, where machining different materials and shapes requires customized feed rates and cutting forces, the gear-rack system ensures stable cutting performance, high machining precision, and adaptability across diverse processing tasks.

High-Precision Motion Control for Smooth Operation

For high-precision equipment, motion control accuracy is non-negotiable. Yuchen’s helical gear, manufactured to DIN6 tolerance and ground to micron-level precision, delivers exceptional motion control when paired with ground racks. In photolithography machines used in semiconductor manufacturing, this gear ensures smooth and precise movement of the exposure head, enabling accurate circuit pattern etching on chips. Even under prolonged operation, it maintains stable accuracy, reduces vibration and noise, and provides a solid foundation for high-precision equipment.

Durability and High Load Capacity – Extending Equipment Lifespan

Crafted from premium S45C medium carbon steel or SCM440 alloy steel, the 4M DIN6 Ground Helical Gear undergoes specialized heat treatment to achieve high hardness, wear resistance, and fatigue strength. When integrated with Yuchen racks, the system is capable of withstanding heavy loads and shock impacts. In mining, metallurgy, and other heavy industries, this durable gear-rack pairing ensures reliable long-term performance under harsh conditions, significantly reducing breakdowns and maintenance frequency, extending equipment lifespan, and lowering operational costs—making it a robust and dependable support for industrial productivity.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español