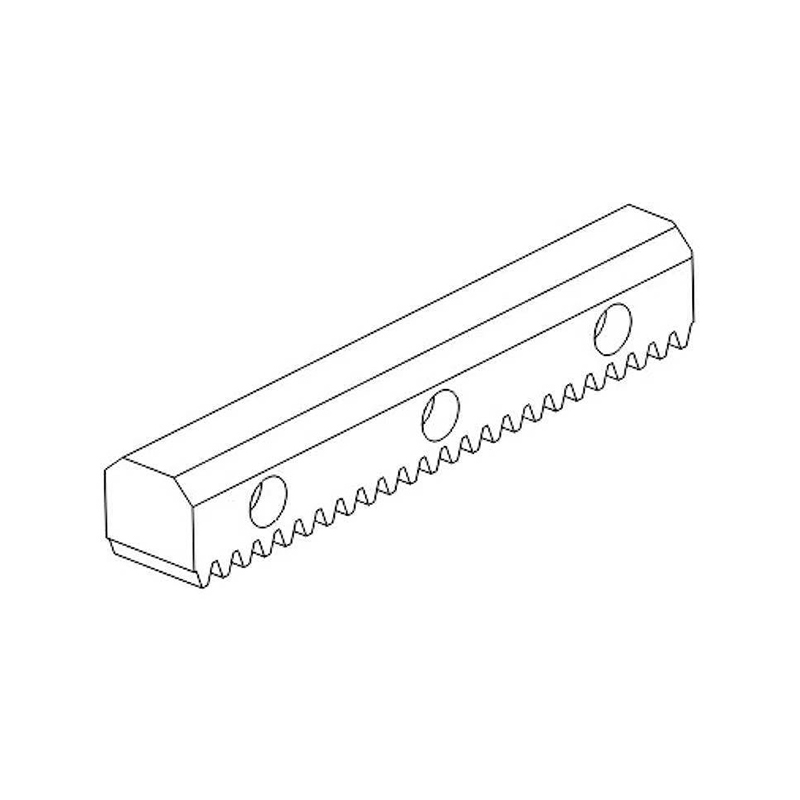

V Type Guideway Rack

DIN6 V-Guide Ground Spur Gear Rack

Specifications:

Accuracy level: DIN6

Material: S45C/42CrMo

Tooth type:straight tooth

Hardening Treatment: High-frequency quenching (HRC 48-52°) / Carburizing and quenching (HRC 55-60°)

Production process:four sides grinding, tooth surface grinding, V rail surface grinding.

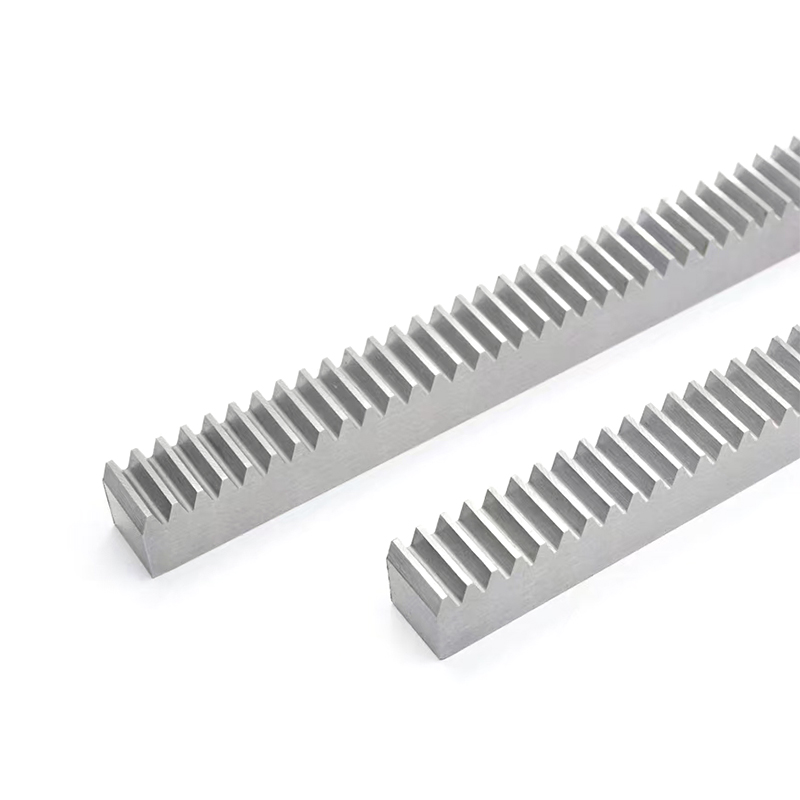

In the field of industrial transmission, precision and stability remain the fundamental goals. Yuchen’s V-Guide straight tooth ground gear rack delivers reliable transmission solutions for your equipment through advanced craftsmanship and outstanding performance.

Manufactured from high-quality S45C and 42CrMo materials and subject to stringent quality control, Yuchen ensures good strength and toughness of the gear racks. The unique V-guide straight tooth design, combined with high-precision grinding processes, guarantees the accuracy and quality of each gear rack. Both the tooth surface and the V-guide surface undergo fine grinding to achieve nice flatness and surface finish, effectively reducing friction and enabling smoother and more stable motion.

Product Features:

High-Precision Guidance: The V-shaped structure limits the degrees of freedom of moving components, ensuring stable direction and position during linear motion. This results in high guiding accuracy suitable for equipment demanding precise position control, such as CNC machine tools and automated production lines.

Strong Load Capacity: Made from high-strength materials, the gear rack can withstand substantial axial forces, radial forces, and torque. It is well-suited for various heavy-duty applications, including heavy machinery manufacturing, providing reliable support for moving components and ensuring normal operation.

Easy Installation and Maintenance: The standardized installation method allows for seamless integration with diverse machinery. Routine inspection and cleaning, along with timely replacement of worn parts, simplify maintenance and reduce downtime and costs.

nice High-Speed Performance: The V-guide structure reduces friction between moving parts and the guide rail, lowering energy consumption and enhancing motion efficiency. The rack-and-pinion transmission ensures high-speed and smooth linear motion, meeting the requirements of automated logistics systems and other high-speed applications.

Applications:

Widely used in industrial automation, CNC machine tools, robotics, logistics equipment, and other fields. Typical applications include robotic arm gripping mechanisms on automated production lines, CNC machine tool table movement, robot locomotion systems, and conveyor equipment in logistics and warehousing.

Yuchen’s V-Guide straight tooth ground gear rack provides your industrial equipment with precise, stable, and efficient transmission support. Choosing Yuchen means choosing quality and reliability.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español