Spur Gear Rack

DIN8 Precision-Milled & Tempered Spur Gear Rack

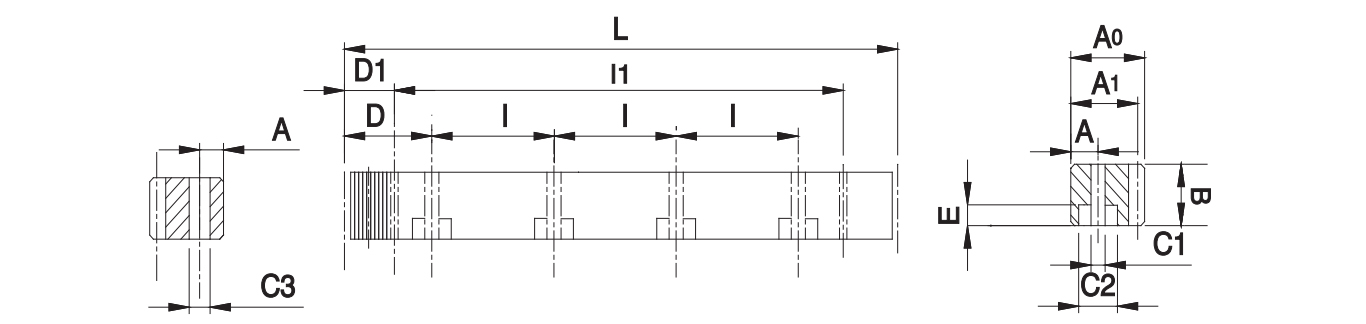

Specifications:

Precision Grade: DIN 8e27

Material: C45 / 40Cr / 42CrMo

Type: Straight Rack

Treatment of Teeth: Milled

Hardness: Overall Quenching, HRC18–20; no high-frequency surface hardening

Sides Ground: Included

Pressure Angle: 20°

Total Pitch Error: 0.08mm/1000mm

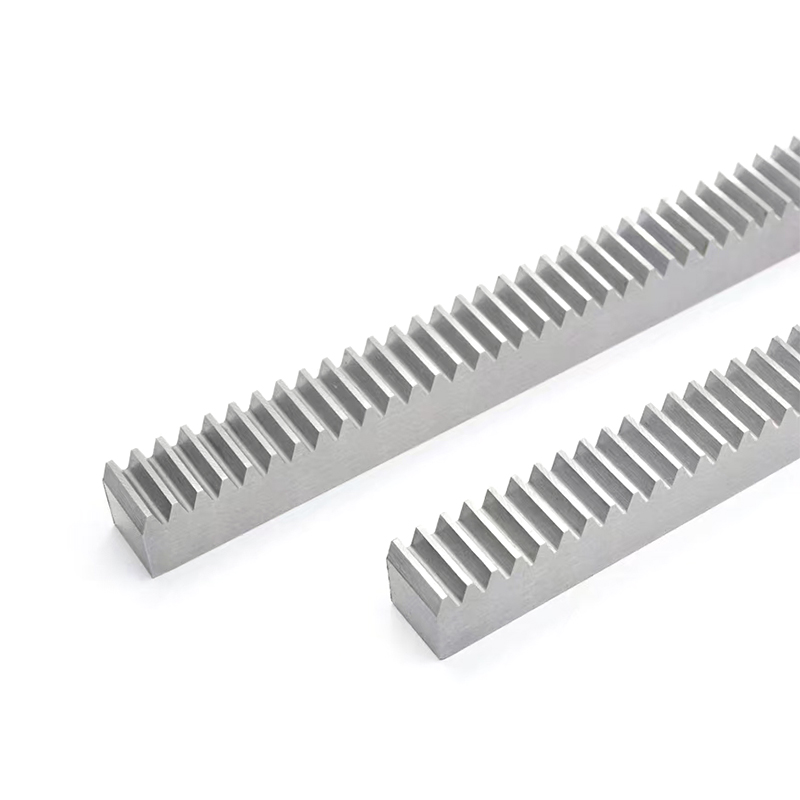

Yuchen's tempered spur gear rack is engineered for precision transmission systems across a wide range of industrial machinery. With stable performance and good durability, it offers a reliable power transmission solution tailored for automation, CNC systems, woodworking, laser cutting, and packaging equipment.

Advanced Manufacturing for Reliable Quality

Each gear rack is manufactured using high-precision CNC machines and adheres to strict quality standards from material selection to final inspection. We use carefully selected alloy steels such as S45C (equivalent to C45), known for their balance of strength and toughness. Critical parameters such as tooth profile and spacing are precisely controlled during the milling process to ensure less gear tooth deviation and high compatibility with mating gears.

Tempering Process for Enhanced Mechanical Properties

Tempering is a core treatment in the production of Yuchen gear racks. By heating the rack to an nice temperature followed by controlled cooling, the steel's microstructure is refined for improved strength, toughness, and fatigue resistance. This treatment results in a surface hardness of HRC18–20, improving wear resistance without compromising flexibility. The racks can endure continuous operation under high loads and variable conditions while maintaining dimensional stability and mechanical reliability.

Versatile Applications Across Industries

Thanks to its robust design and dependable performance, the tempered gear rack is widely applied in:

Industrial Automation Systems: Assisting robotic arms in achieving precise movement and positioning.

CNC Machinery: Ensuring tool movement accuracy for high-precision cutting and milling.

Woodworking Machinery: Supporting smooth and accurate feeding during cutting and carving operations.

Laser and Packaging Equipment: Facilitating synchronized mechanical movements and improving process efficiency.

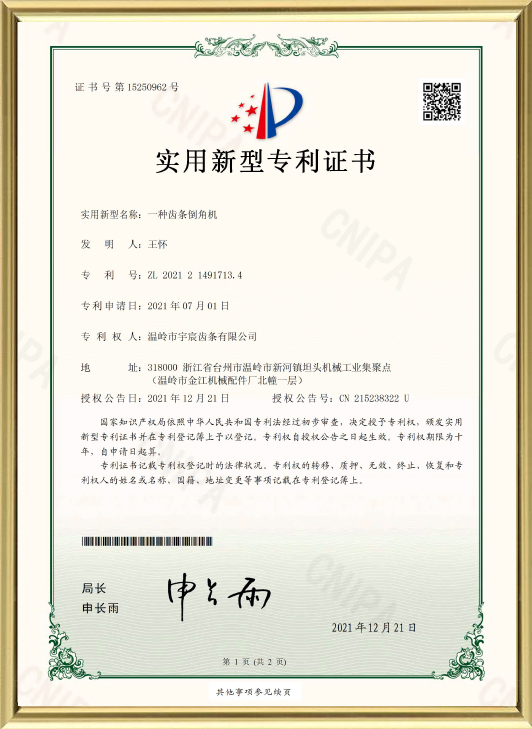

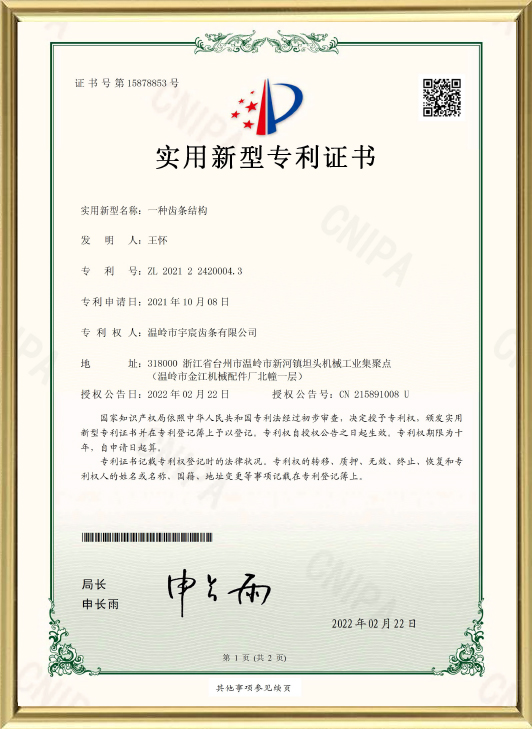

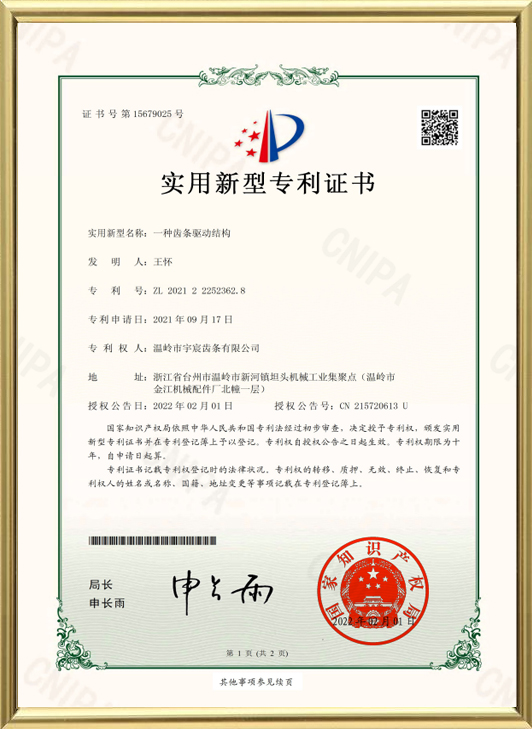

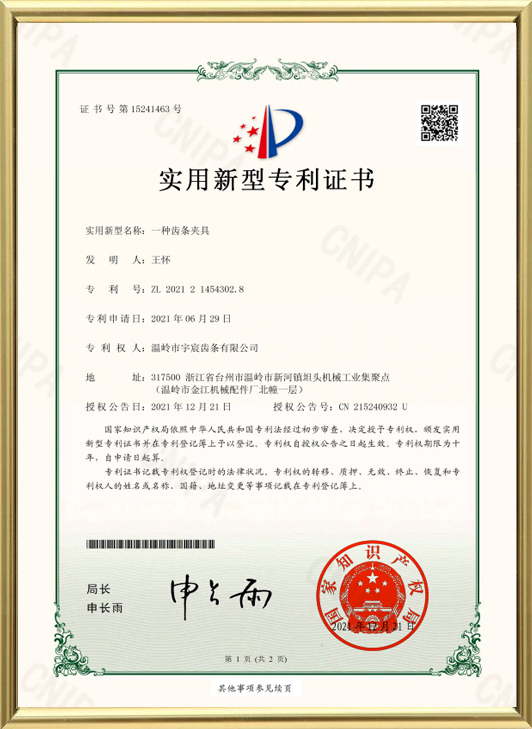

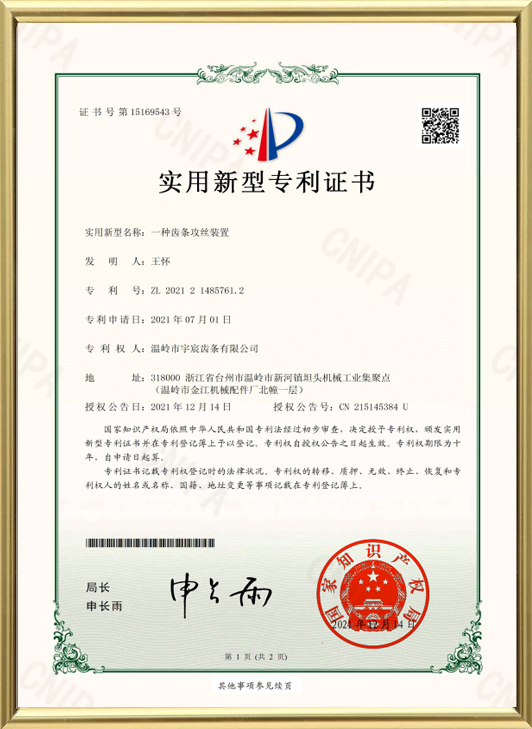

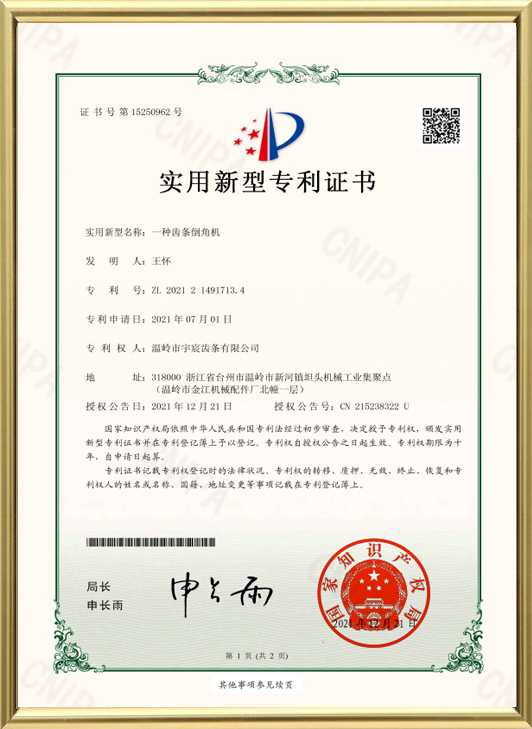

Strict Quality Control Ensures Dependable Results

Yuchen implements a comprehensive quality control system, certified to ISO 9001 standards. From raw materials to final assembly, every step is inspected using advanced equipment including coordinate measuring machines (CMMs) and gear measuring instruments. Only products that meet strict dimensional and tolerance specifications are approved for shipment.

By choosing Yuchen’s DIN8 precision-milled & tempered spur gear rack, you invest in a high-performance, dependable transmission solution backed by years of manufacturing experience. With consistent quality, technical expertise, and dedicated support, Yuchen is your trusted partner in the field of industrial motion control.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español