Spur Gear Rack

DIN10 Precision-Milled & Hardened Spur Gear Rack

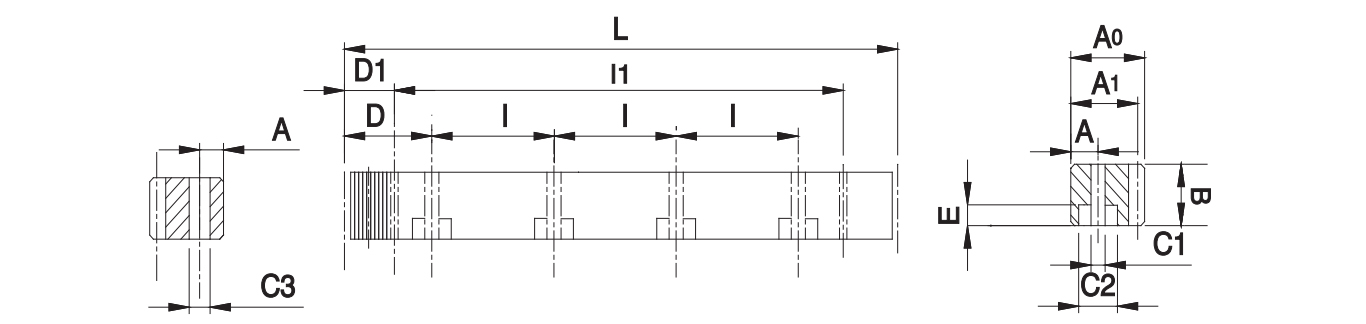

Specifications

Precision Grade: DIN 10e27

Material: C45 / 40Cr / 42CrMo

Type:Straight Rack

Treatment of Teeth: Milled

Hardness: Overall Quenching & Tempering; Tooth Surface Induction Hardened to HRC 50–55

Sides Ground: Included

Pressure Angle: 20°

Total Pitch Error: 0.13mm/1000mm

Surface Treatment: Full Black Oxide / Phosphating Available

In the world of mechanical transmission, Yuchen’s precision-milled spur gear racks stand out as a reliable choice for industries demanding stability, accuracy, and durability.

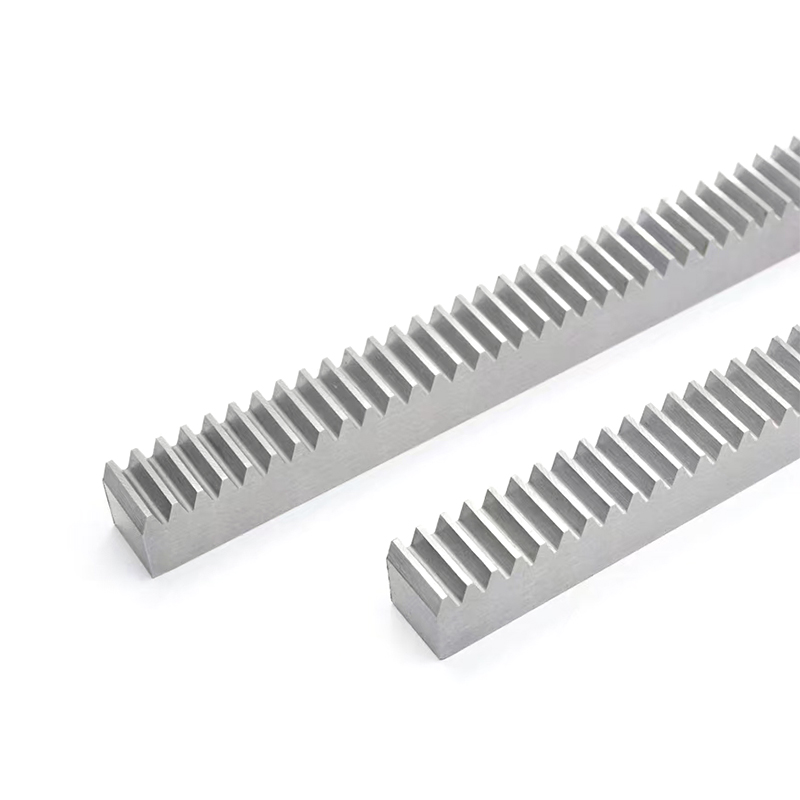

Precision Milling for good Accuracy

Yuchen adopts advanced CNC milling techniques operated by skilled professionals to ensure precise gear cutting and consistent pitch accuracy. From gear design to machining, every detail is meticulously controlled to achieve less profile deviation and stable engagement with mating gears. This level of precision ensures exceptionally smooth operation, reduced vibration, and low noise, making it ideal for precision-driven machinery and demanding motion systems.

High-Quality Steel for Structural Durability

Yuchen gear racks are made from carefully selected steels such as C45 medium carbon steel, offering nice strength and wear resistance. Through strict quenching and tempering processes, the internal structure of the material becomes uniform, with a core hardness of HRC 18–22. The tooth surface is then hardened to HRC 50–55 via high-frequency induction hardening, enabling the rack to withstand heavy loads and frequent shocks, even under harsh working conditions. This enhances overall service life and reduces maintenance costs significantly.

Surface Treatment for Enhanced Performance

To improve corrosion resistance and surface smoothness, the gear racks undergo black oxide or phosphating treatment. The resulting dense oxide layer protects the surface from environmental moisture and chemicals, while also lowering the friction coefficient. This boosts transmission efficiency and ensures smoother motion, helping to reduce energy consumption in industrial systems.

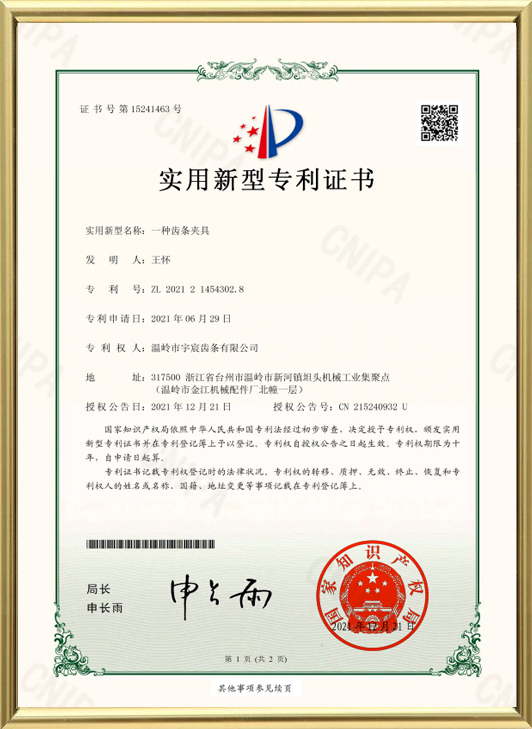

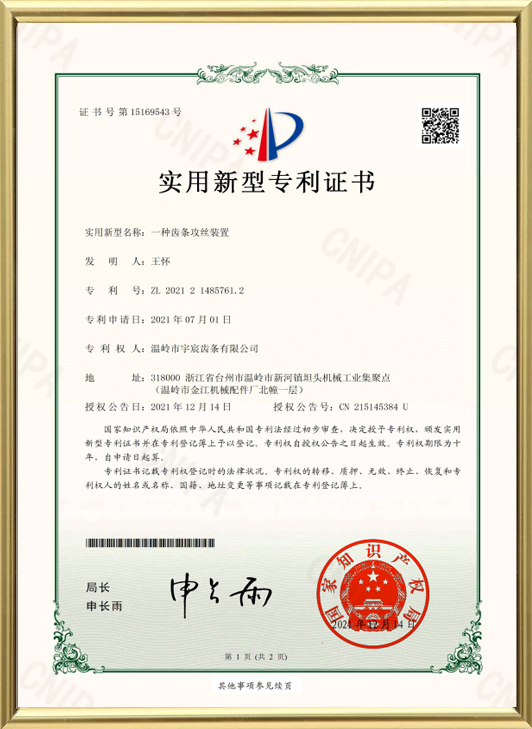

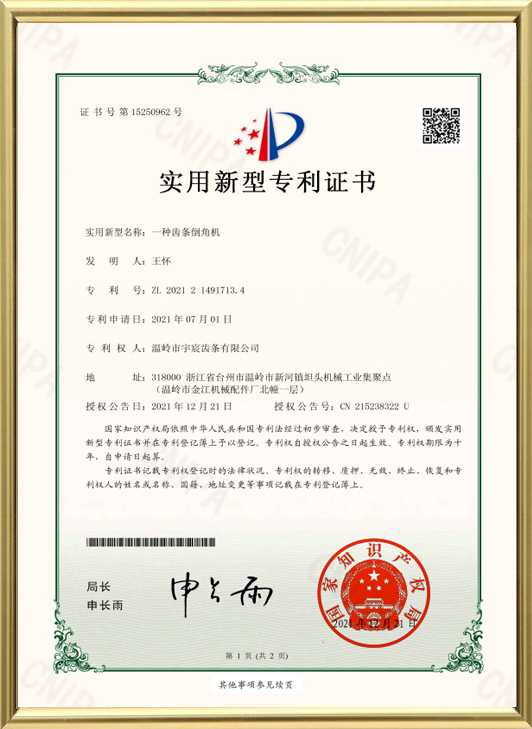

Rigorous Quality Control for Dependable Results

Yuchen maintains a comprehensive quality management system. From raw material selection to final inspection, every process is tightly monitored. Advanced metrology tools, such as coordinate measuring machines (CMM) and gear testers, are used to verify critical dimensions and tolerances. Only products that meet ISO 9001 standards are released, ensuring every rack delivers consistent and reliable performance.

Versatile Applications Across Industries

Yuchen precision-milled spur gear racks are widely used in automation systems, CNC machines, laser cutting machines, woodworking equipment, and packaging machinery. In automated lines, they enable accurate robotic positioning and rapid motion control. On CNC platforms, they ensure precise tool travel for high-accuracy machining. For woodworking, they provide stability during cutting and carving operations. Wherever mechanical precision is essential, Yuchen gear racks provide a dependable solution.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español