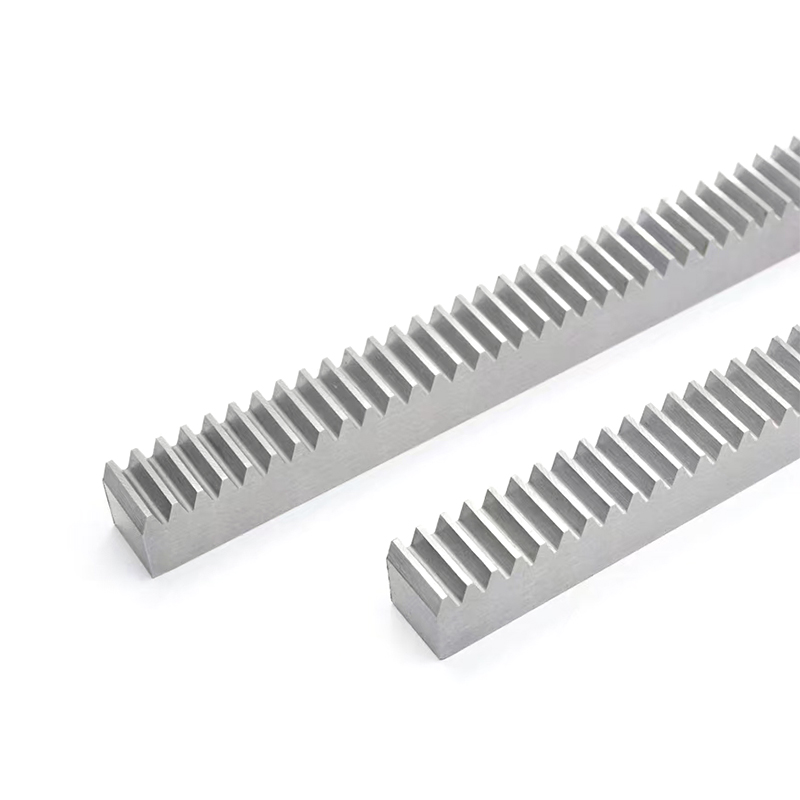

Helical Gear Rack

DIN8 Precision-Milled & Tempered Helical Gear Rack

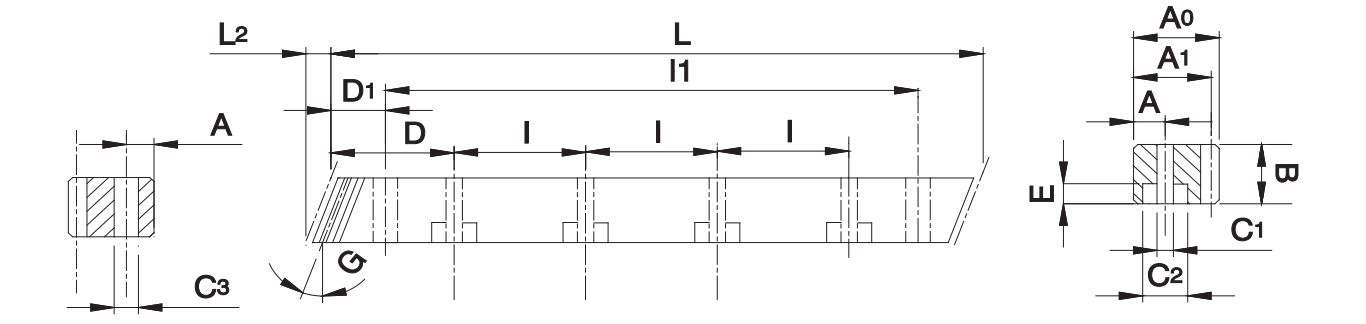

Specifications:

Precision Grade: DIN8e27

Material: C45 / 40Cr / 42CrMo

Type: Helical Rack

Treatment of Teeth: Milled

Hardening Treatment: Overall tempering to HRC18–20; no high-frequency surface hardening

Sides Ground: Included

Right hand angle: 19°31'42”

Pressure Angle: 20°

Total Pitch Error: 0.08mm/1000mm

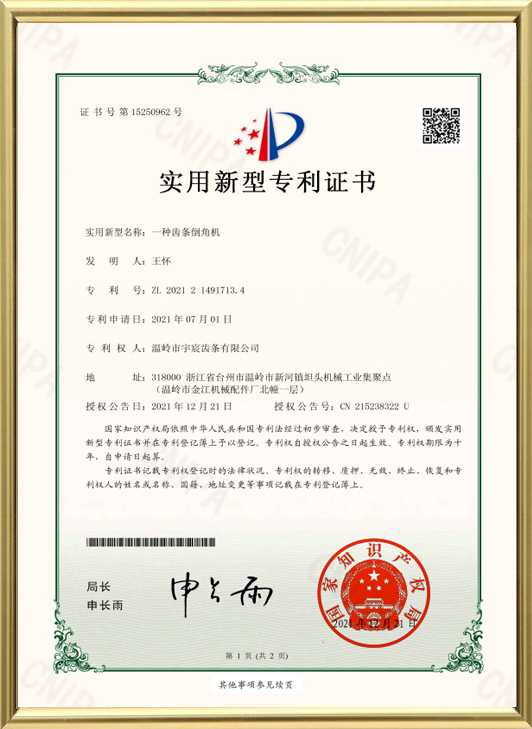

The DIN8-grade helical gear rack by Yuchen is a medium-precision linear transmission component designed in compliance with DIN standards. It is well-suited for general automation and positioning applications where ultra-high precision is not mandatory.

Precision Performance:

Manufactured to DIN 8 tolerance, the gear rack offers controlled tooth profile and cumulative pitch errors. It ensures reliable linear motion and repeatable positioning in systems such as standard CNC engraving machines and automated assembly lines.

Materials & Processing:

The gear racks are commonly produced from C45 steel or medium-carbon alloy steels such as 40Cr and 42CrMo. After undergoing a tempering process, the overall tooth body reaches a hardness of HRC18–22, achieving a balance between wear resistance, strength, and toughness. This makes the gear rack capable of withstanding moderate impact loads in dynamic environments.

Key Features:

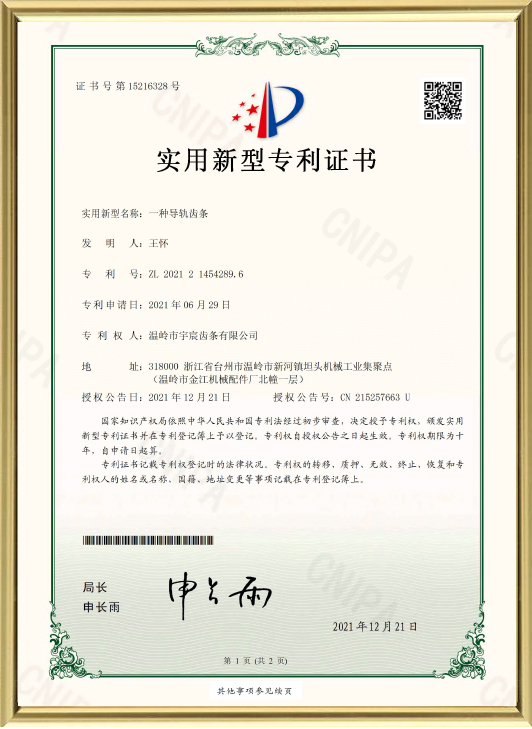

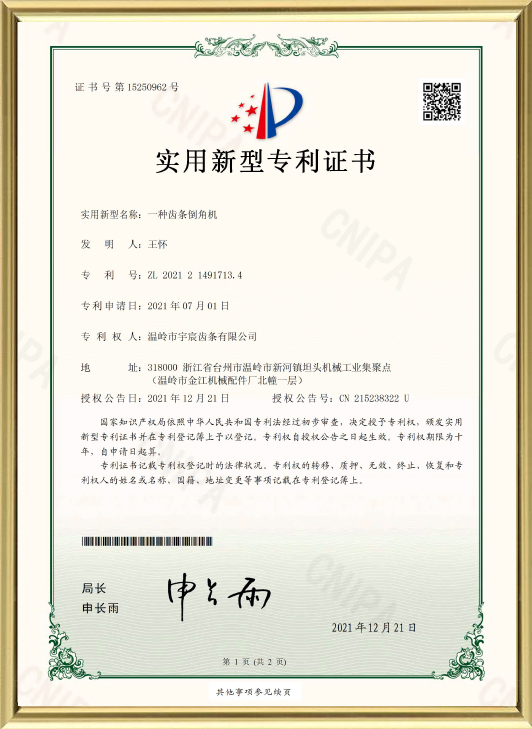

Yuchen utilizes advanced production equipment and a rigorous quality control system to deliver helical gear racks with smooth operation and low noise. Customization is available for parameters such as module, length, and special profiles to accommodate various non-standard applications.

Applications:

These gear racks are widely used in industrial automation, including gantry robots, conveyor systems, woodworking machinery such as engraving and edge-banding machines, and packaging equipment like filling and sorting systems. They provide a stable and reliable solution for linear transmission in demanding industrial settings.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español