Helical Gear Rack

DIN10 Precision-Milled & Hardened Helical Gear Rack

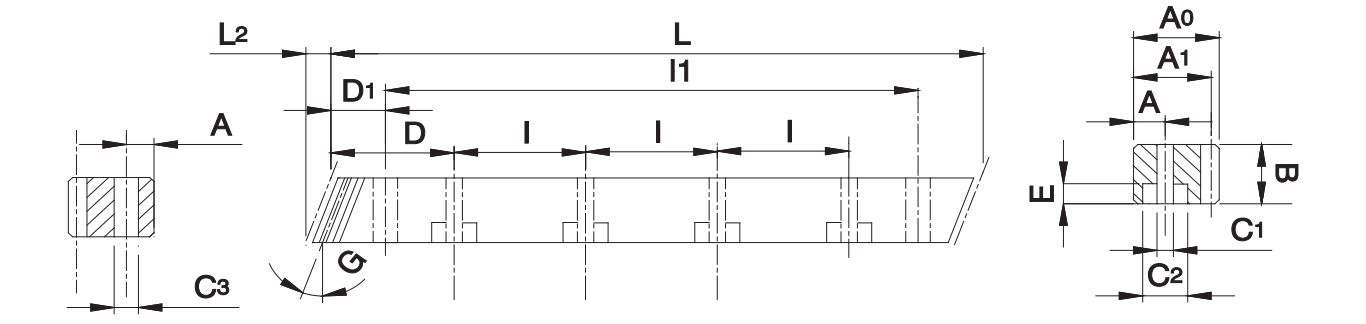

Specifications:

Precision Grade: DIN10e27

Material: C45 / 40Cr / 42CrMo

Type: Helical Rack

Treatment of Teeth: Milled

Hardness Treatment: Full-body tempered HRC18–20; Tooth surface induction hardened to HRC50–55

Sides Ground: Included

Right hand angle: 19°31'42”

Pressure Angle: 20°

Total Pitch Error: 0.13mm/1000mm

Surface Treatment: Black Oxide / Phosphating

In the field of industrial power transmission, the YUCHEN precision-milled and induction-hardened helical gear rack stands out with its high performance, making it a preferred choice across various industries.

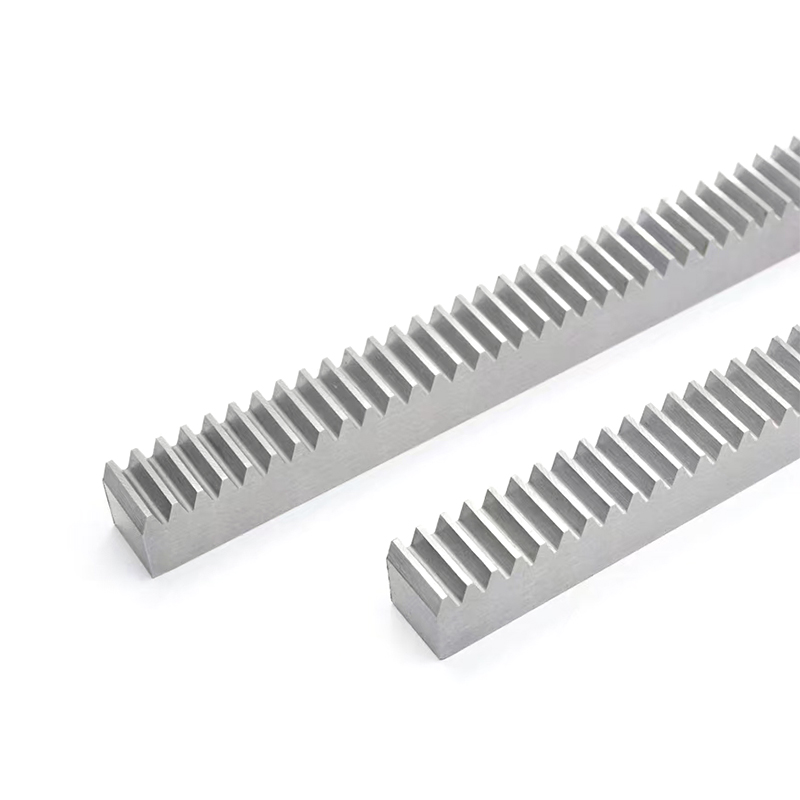

Precision Milling for Accurate Tooth Profiles

YUCHEN applies advanced CNC gear milling techniques to achieve highly accurate tooth geometry. Utilizing state-of-the-art milling machinery, every parameter is meticulously controlled to produce gear teeth with exceptional dimensional and profile accuracy. The less pitch deviation ensures smooth meshing between gear and rack, resulting in low noise and vibration. This stability is essential for high-performance systems, supporting efficient and reliable operation.

Hardened for Strength and Wear Resistance

Heat treatment is a vital process in enhancing the gear rack’s performance. YUCHEN adopts an optimized hardening technique that tempers the entire rack body (HRC18–20) and applies induction hardening to the tooth surface, achieving a hardness of HRC50–55. This treatment significantly increases surface wear resistance and fatigue strength, enabling long-lasting performance even under heavy loads, frequent start-stop cycles, and harsh working conditions. The result is extended product life and reduced maintenance costs.

Black Oxide Coating for Corrosion Protection

Beyond its technical attributes, the black oxide finish gives the gear rack a professional appearance while offering essential surface protection. The formed oxide layer resists oxidation and moisture, enhancing corrosion resistance in humid or chemically aggressive environments. Additionally, the blackened surface reduces friction during operation, contributing to improved transmission efficiency and smoother motion.

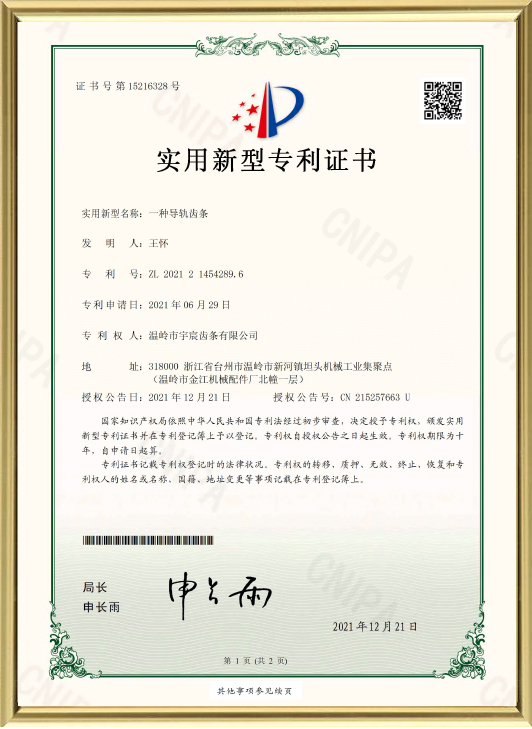

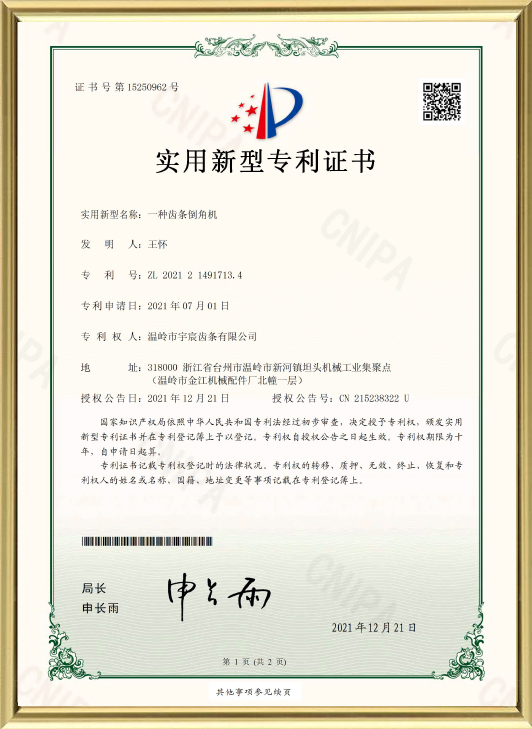

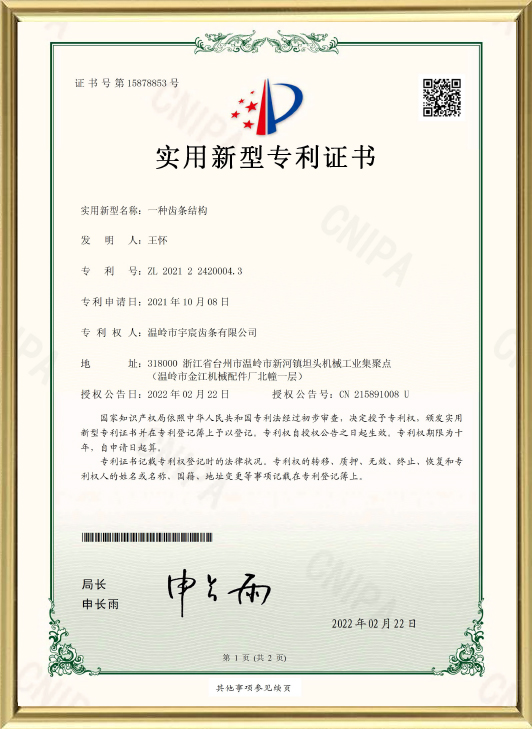

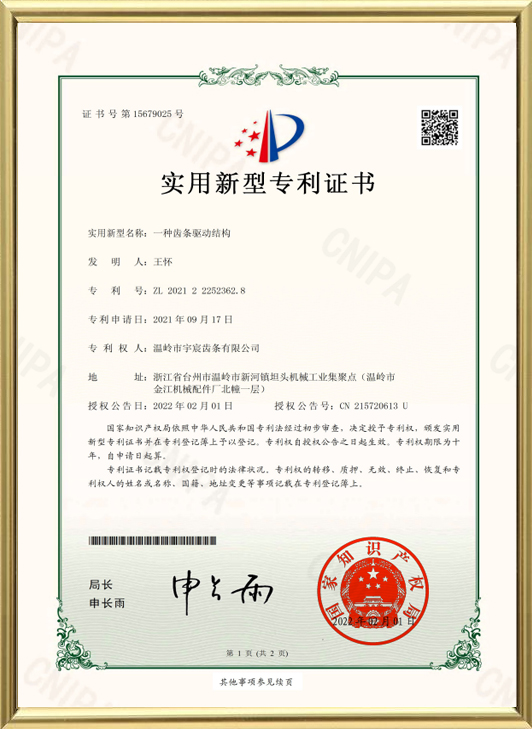

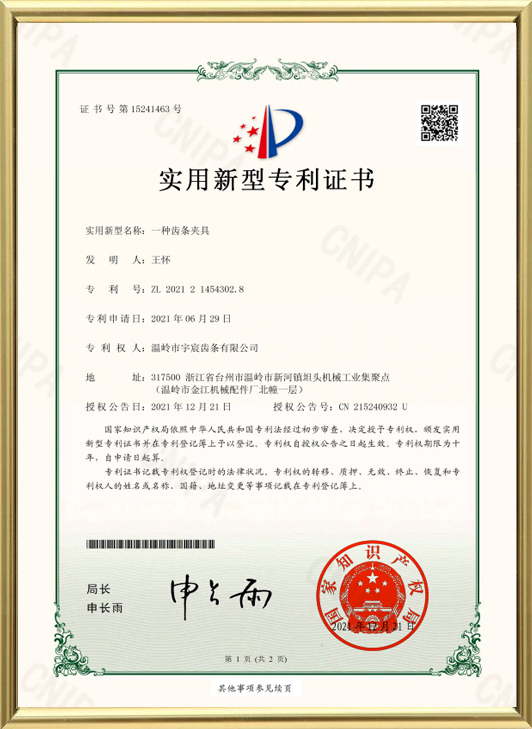

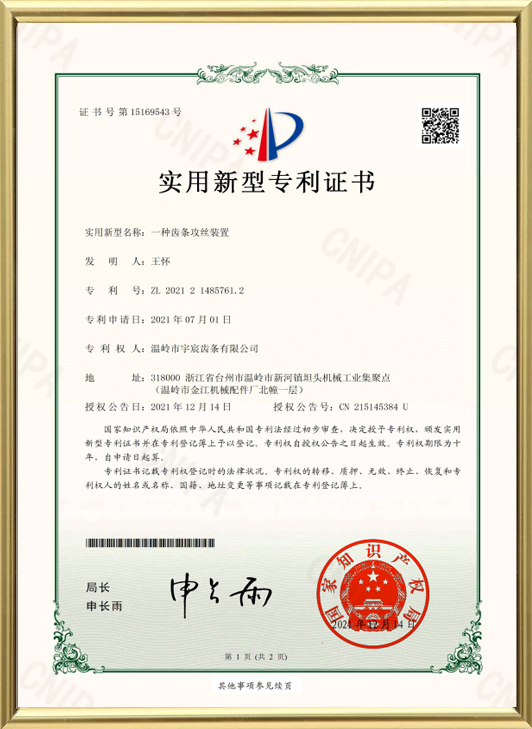

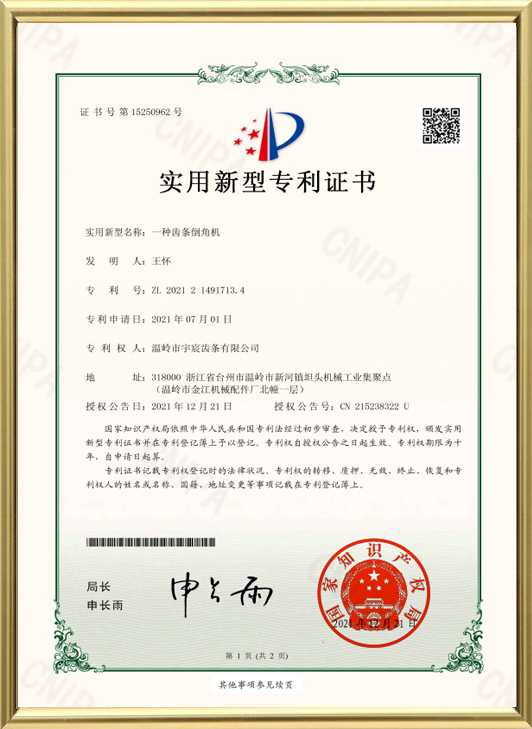

Rigid Quality Control Ensures Consistent Performance

From material selection to final inspection, YUCHEN operates under a stringent quality management system. Premium-grade steel is sourced to ensure consistent material properties. During production, sophisticated measuring tools such as coordinate measuring machines (CMMs) are used to inspect dimensional and geometrical tolerances. The product undergoes up to 18 quality control procedures, and only gear racks fully compliant with ISO9001 standards are approved for shipment—guaranteeing reliable quality in every unit.

YUCHEN DIN10 precision-milled, hardened, and blackened helical gear racks are widely used in automation systems, CNC machinery, laser cutting machines, woodworking equipment, and more. If you are seeking a robust and precise gear rack solution, contact YUCHEN today. We are ready to provide tailored solutions and professional service for your industrial needs.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español