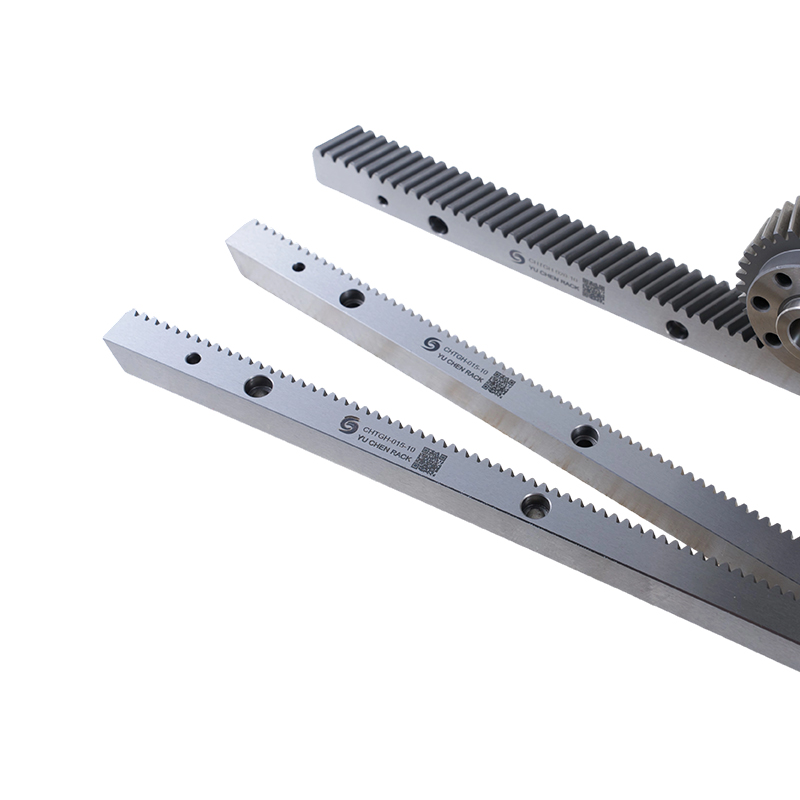

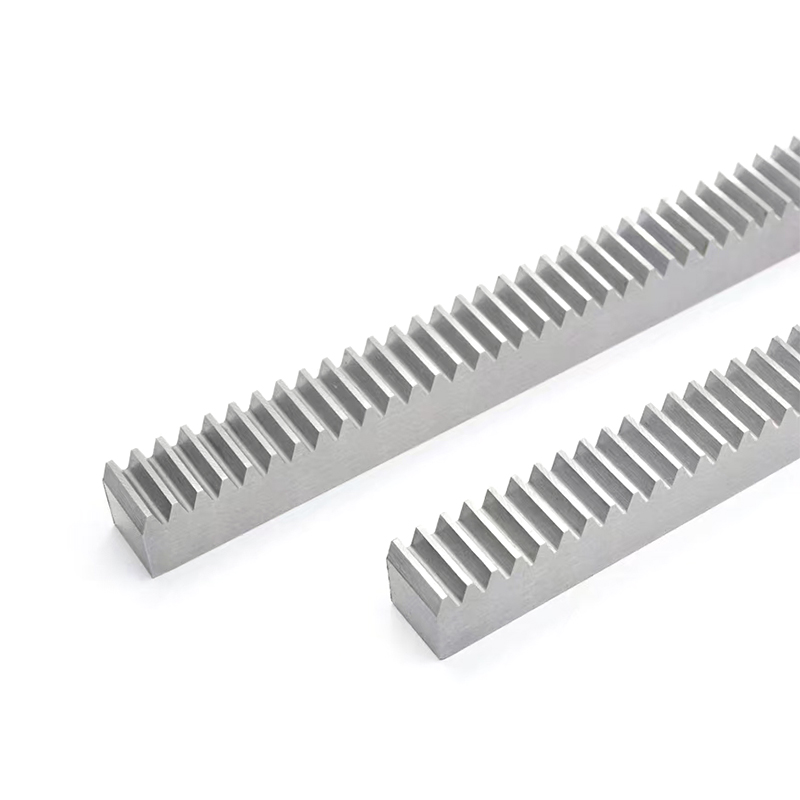

Helical Gear Rack

DIN6 High-Precision Ground & Hardened Helical Gear Rack

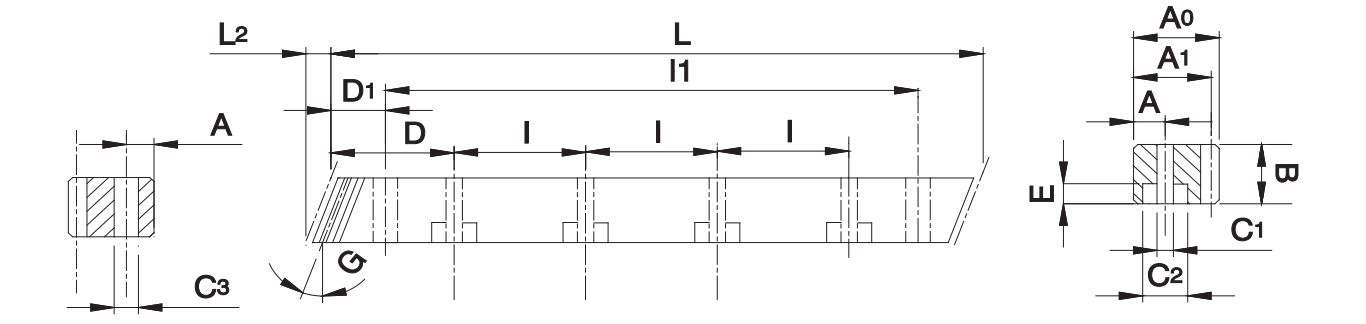

Specifications:

Precision Grade: DIN6h25

Material: C45 / 40Cr / 42CrMo

Type: Helical Rack

Treatment of Teeth: Ground

Hardening Process: Overall Quenching + Tooth Surface Induction Hardening (HRC50–55)

Sides Ground:Included

Right hand angle: 19°31'42”

Pressure Angle: 20°

Total Pitch Error: 0.036mm/1000mm

Yuchen’s high-precision ground helical gear rack is a standout innovation, engineered to meet the evolving demands of high-end motion systems. With decades of expertise in mechanical transmission, Yuchen integrates advanced machining techniques, good materials, and rigorous quality control to deliver a gear rack that redefines performance in precision applications.

Precision Machining Beyond the Ordinary

Manufactured using state-of-the-art five-axis gear grinding centers, this rack undergoes ultra-fine micro-level grinding. The gear surface roughness is reduced to Ra ≤ 0.8, with a tooth profile error strictly controlled within ±5μm. Achieving ISO Grade 6 or higher, the rack offers mirror-like surface quality, ensuring ultra-smooth, backlash-free engagement. This enables less vibration, stable operation, and consistent accuracy—an essential foundation for advanced automation systems and CNC equipment.

Advanced Materials and Heat Treatment

Only high-strength materials like SCM440 alloy steel are selected to meet demanding industrial conditions. Through a vacuum carburizing and quenching process, the gear surface forms a hardened layer of up to 2.5mm, reaching HRC50–55 in hardness. This significantly enhances wear resistance, fatigue strength, and dynamic load capacity (up to 2000N/mm²), tripling the product’s lifespan compared to conventional gear racks. Users benefit from reduced maintenance frequency and lower replacement costs over time.

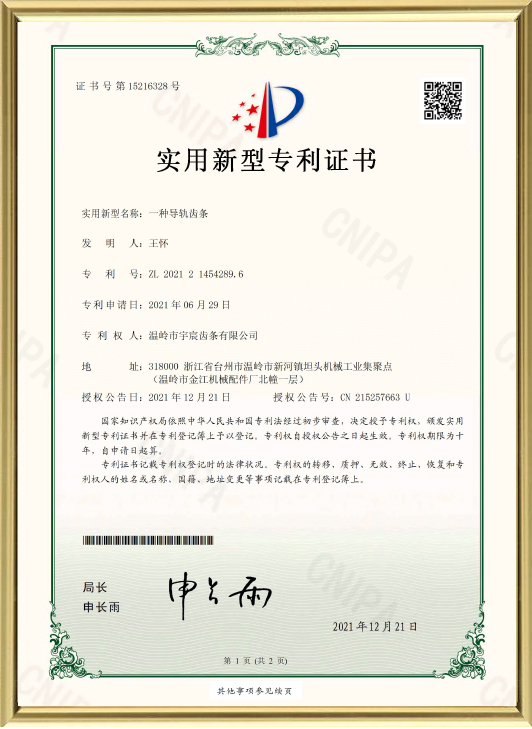

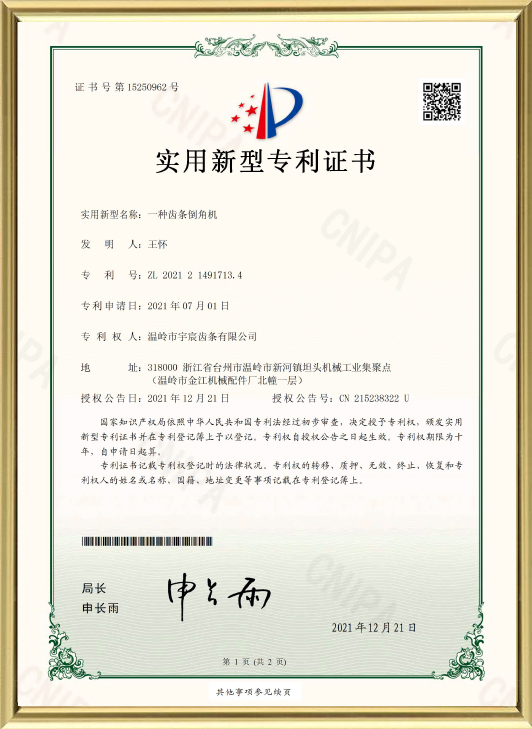

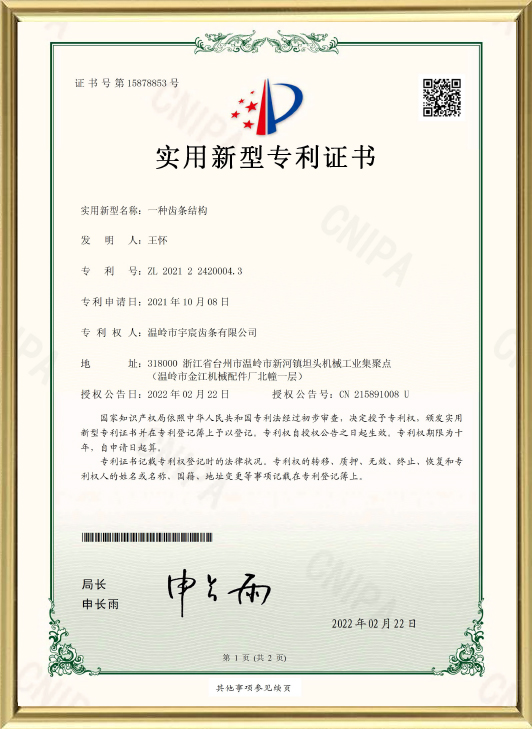

Uncompromising Quality Control

Each gear rack undergoes 18 strict quality control procedures from raw material entry to final delivery. Equipped with CMMs and precision gear measurement centers, Yuchen ensures that every rack is fully inspected for dimensional accuracy and gear conformity. Products are delivered in full compliance with ISO 9001:2015 standards, guaranteeing stable, high-level performance.

Proven Reliability in Demanding Applications

In robotics, the rack’s ±20μm positioning accuracy enables robotic arms to perform precision assembly with ease. On high-performance CNC machine tools, the accumulated pitch error of just 0.036mm per 1000mm allows consistent micron-level machining. Even in harsh environments such as aerospace testing platforms, optional anti-corrosion coatings allow stable performance under extreme conditions. With its high accuracy, rigidity, and long service life, this gear rack is increasingly favored by major manufacturers and has emerged as a strong domestic alternative to imported components.

Driving the Future of Precision Motion

The success of Yuchen’s ground helical gear rack marks a pivotal moment in China’s progress toward independent innovation in precision transmission. It not only reflects Yuchen’s engineering capabilities but also contributes robust support to the upgrade of smart manufacturing across various sectors. From the lab to the workshop, it exemplifies the strength and potential of Chinese precision engineering on the global stage.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español