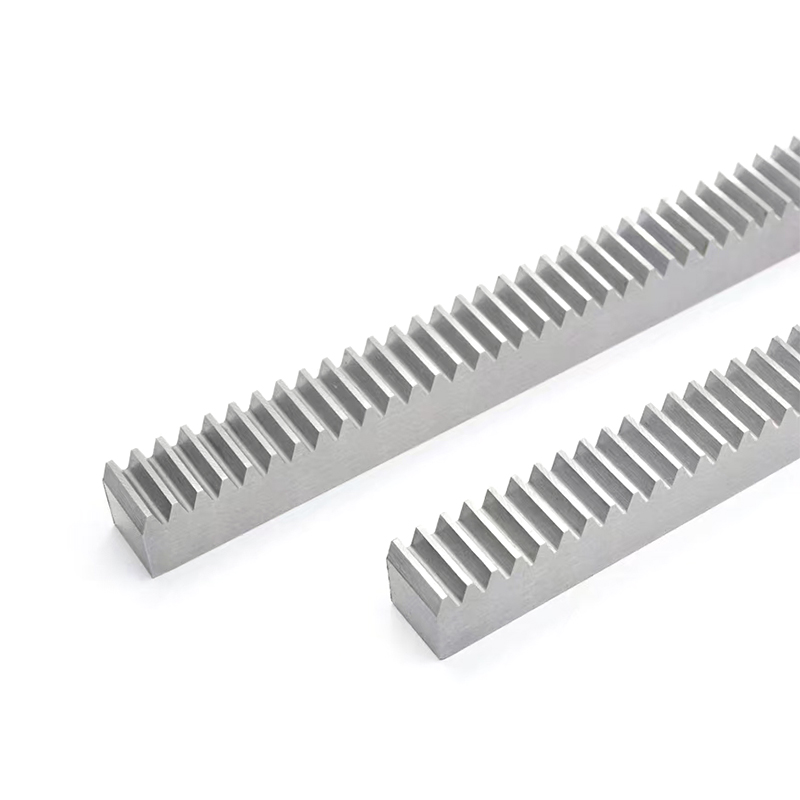

Spur Gear Rack

DIN6 High-Precision Ground & Hardened Spur Gear Rack

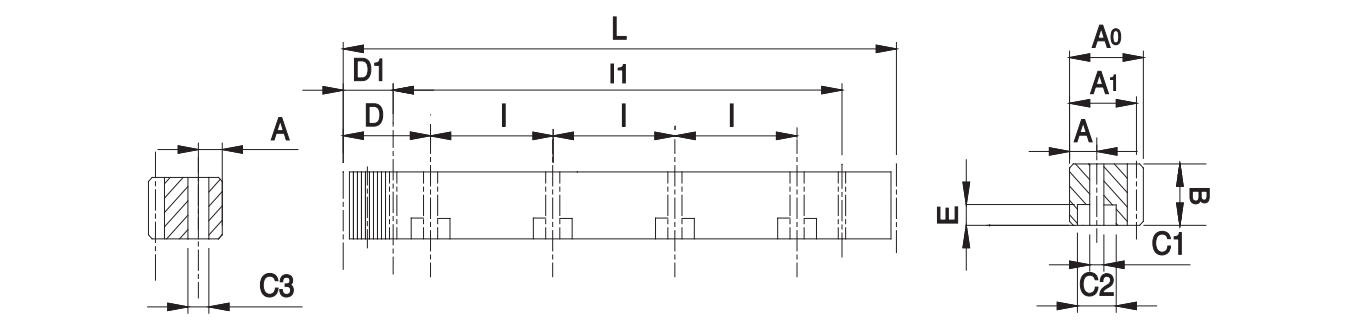

Specifications:

Precision Grade: DIN 6h25

Material: C45 / 40Cr / 42CrMo

Type: Straight Rack

Treatment of Teeth: Ground

Hardness: Overall Quenching & High-Frequency Tooth Hardening (HRC50–55)

Sides Ground: Included

Pressure Angle: 20°

Total Pitch Error: 0.036mm/1000mm

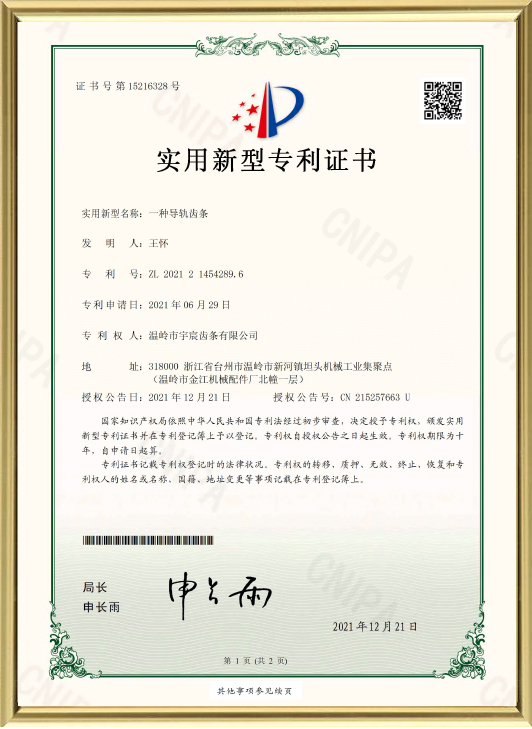

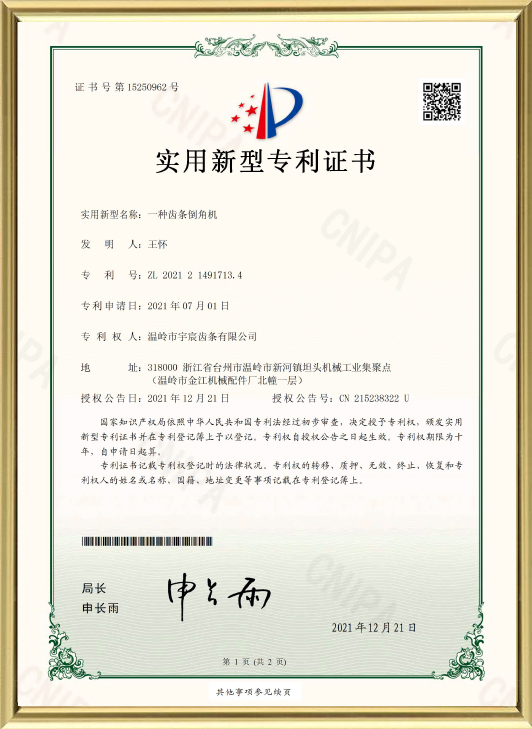

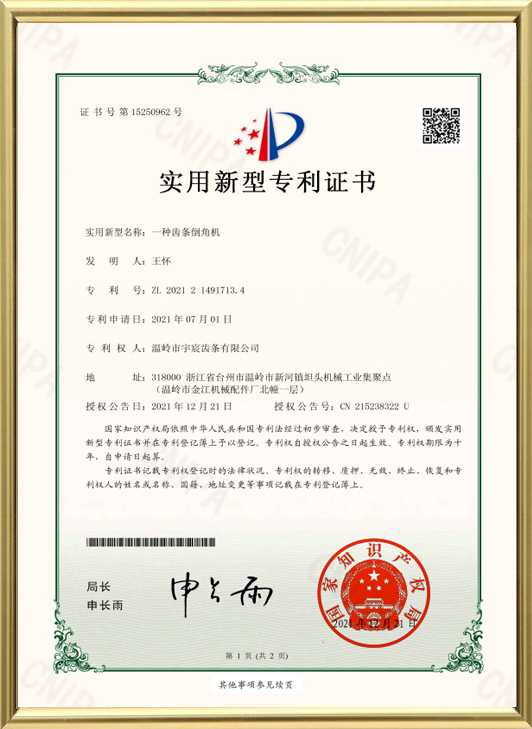

Yuchen Gear proudly presents the DIN6 High-Precision Ground Spur Gear Rack, a product that integrates cutting-edge gear processing technology with durable performance characteristics. Backed by over two decades of industry experience, this gear rack has quickly become a reliable choice across high-end manufacturing applications.

Product Features:

Smooth Transmission with Low Noise

The gear rack is finished with precision grinding, resulting in an exceptionally smooth tooth surface with low roughness. This reduces vibration and noise during meshing with mating gears, ensuring quiet and stable transmission. It is especially suitable for environments with strict noise requirements, such as cleanrooms or precision machinery operations.

High Positioning Accuracy

Engineered with advanced meshing technology, the rack guarantees continuous multi-tooth engagement and near-zero backlash. It offers positioning accuracy within ±20 microns, allowing precise tooth profile location control. This significantly reduces cumulative pitch errors, which is crucial for equipment that requires exact motion control, such as CNC machines and robotic systems, improving machining precision and end-product quality.

Enhanced Corrosion Resistance

Through the use of high-grade materials and optional surface treatments, this gear rack demonstrates nice resistance to corrosion. It performs reliably in harsh conditions, including humid or chemically active environments like those found in food processing or chemical plants. These properties ensure extended service life and consistent equipment performance.

Strict Quality Control & After-Sales Support

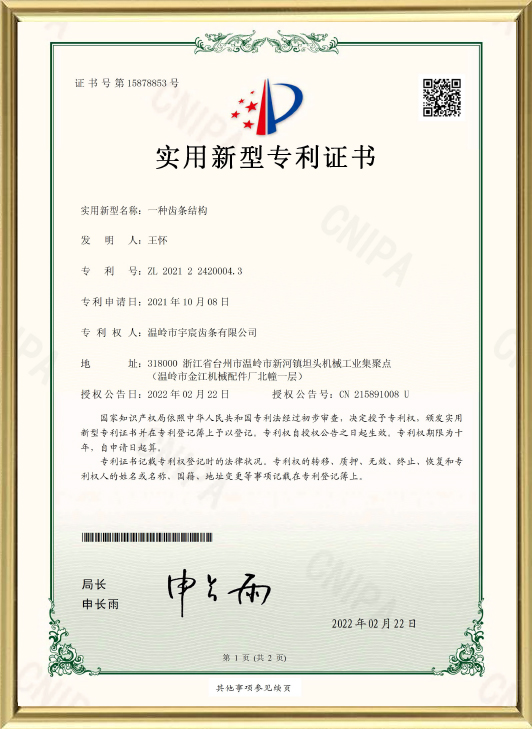

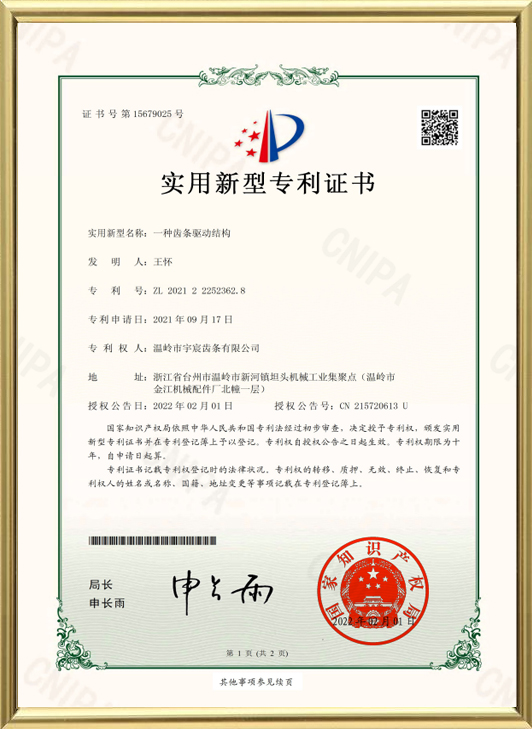

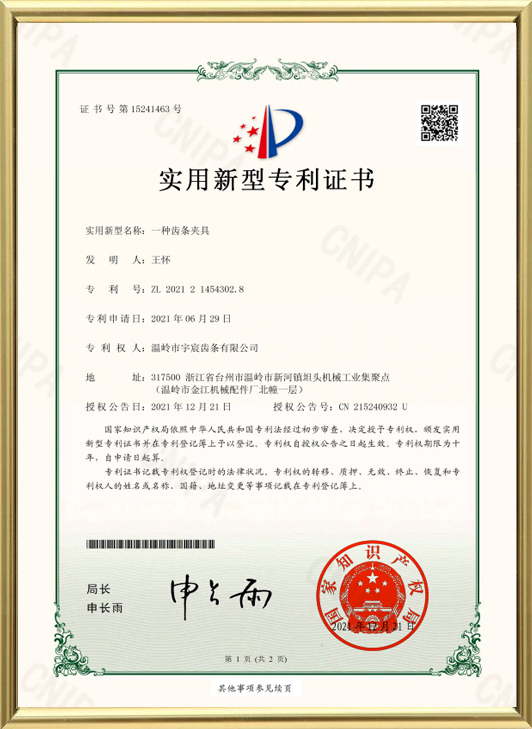

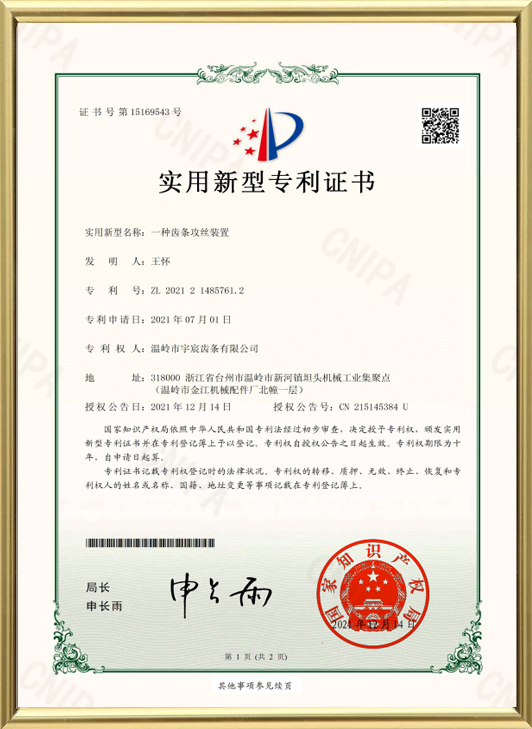

Each rack undergoes 18 quality control checks from raw material selection to final inspection, in full compliance with ISO9001 standards. Yuchen maintains a stringent quality management system and is equipped with state-of-the-art production and testing machinery. In addition to good product reliability, the company offers technical support and professional solutions, helping customers resolve application challenges efficiently, backed by 20 years of practical expertise.

Application Scope:

This spur gear rack is widely used in gantry robots for automated loading and unloading, material handling systems, and palletizing robots. It enables fast and accurate positioning with efficient power transmission, ensuring precision movement and operational flexibility. It supports the reliable operation of automated production lines across various industries.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español