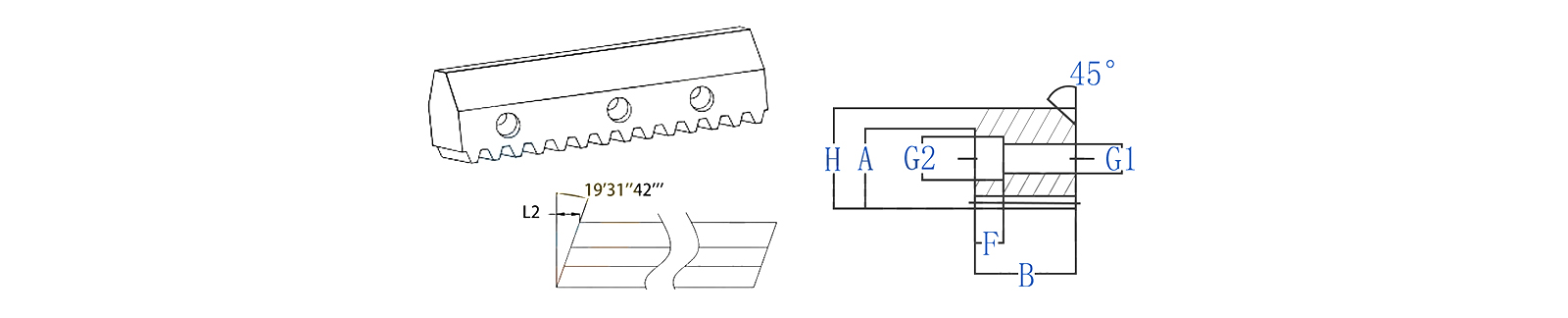

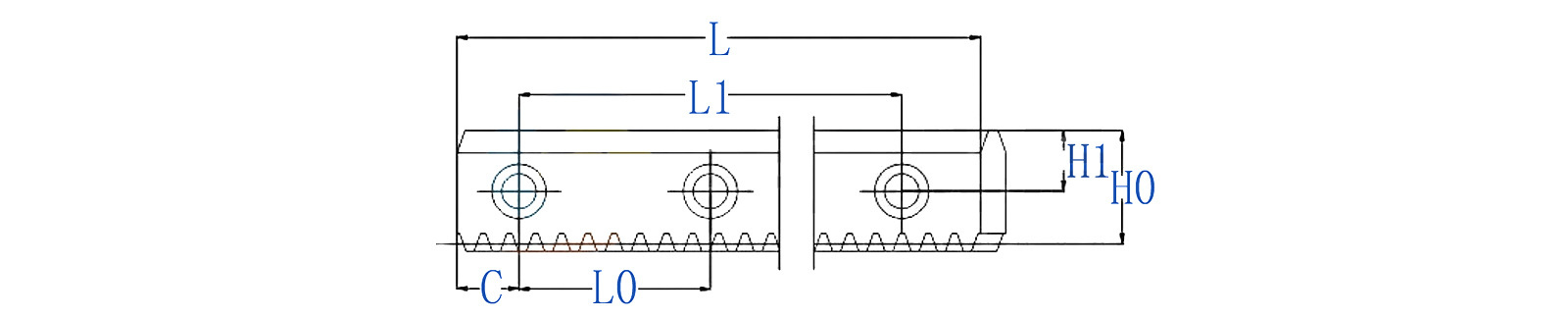

V Type Guideway Rack

DIN6 V-Guide Ground Helical Gear Rack

Specifications:

Accuracy level: DIN6

Material: S45C/42CrMo

Tooth type:helical tooth

Hardening Treatment: High-frequency quenching (HRC 48-52°) / Carburizing and quenching (HRC 55-60°)

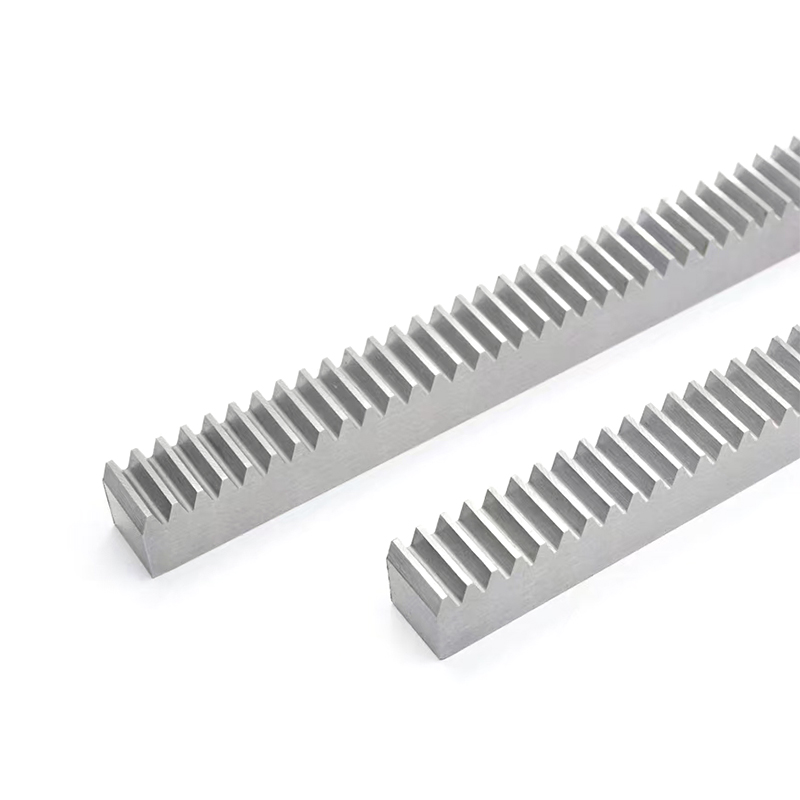

Production process:four sides grinding, tooth surface grinding, V rail surface grinding.

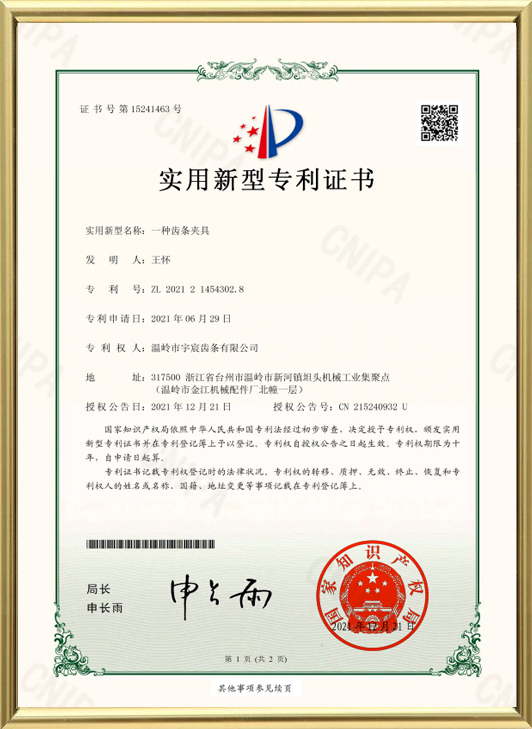

The Yuchen DIN6 V-Guide Ground Helical Gear Rack represents a premium choice for industrial transmission applications where high efficiency and precision are essential. Engineered with advanced manufacturing processes and high-grade materials, this gear rack delivers good performance and durability, meeting the stringent demands of modern industrial equipment.

Advanced Manufacturing and Quality Assurance:

Constructed from premium 42CrMo steel, the gear rack ensures nice strength and toughness from the material level. The manufacturing process involves precision milling and grinding of the teeth, coupled with rigorous multi-stage inspections. The unique V-guide helical tooth design, combined with high-precision grinding on both tooth surfaces and V-guide tracks, guarantees exceptional flatness and surface finish. This results in reduced friction and smoother, more stable linear motion during operation.

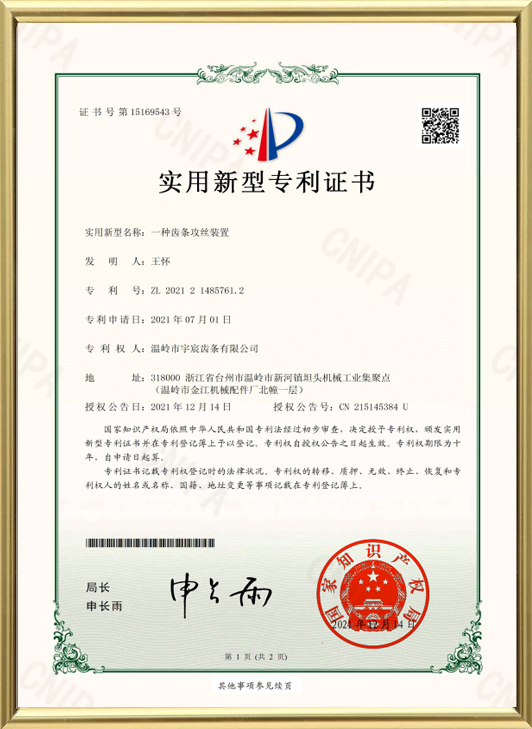

High-Precision Guiding for Accurate Positioning:

The distinctive V-guide structure of this gear rack effectively restricts the degrees of freedom of moving components, ensuring stable directionality and positioning throughout linear motion. This makes it particularly suitable for applications requiring strict positional control, such as CNC machine tools and automated production lines. The Yuchen V-Guide Ground Helical Gear Rack delivers reliable guidance, enabling equipment to achieve tight dimensional tolerances and good surface quality in finished parts.

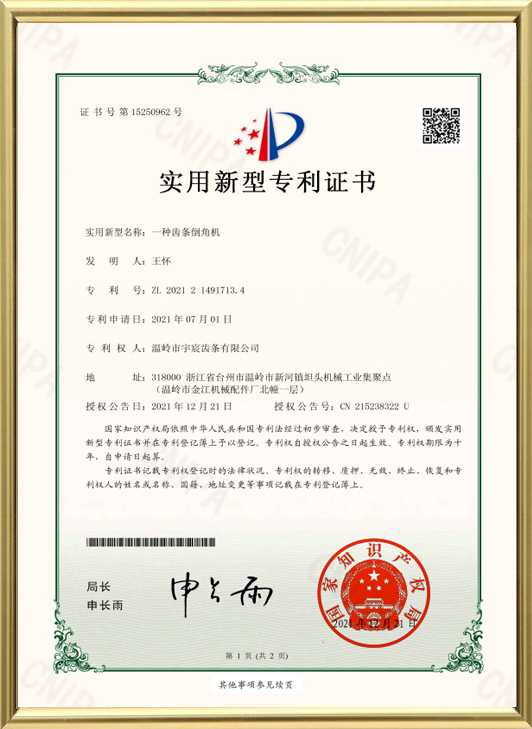

Robust Load Capacity for Heavy-Duty Applications:

Thanks to the high-strength 42CrMo steel and optimized heat treatment, the gear rack exhibits strong load-bearing capacity, capable of withstanding significant axial, radial forces, and torque. It performs reliably in heavy-duty industrial settings where machine components are subjected to substantial weights and impacts. This ensures continuous, stable operation of large-scale equipment.

Ease of Installation and Maintenance:

Designed with standardized installation features, the Yuchen V-Guide Ground Helical Gear Rack can be integrated seamlessly with various machinery without the need for complex tools or techniques. Maintenance is straightforward, involving regular inspection, cleaning, and timely replacement of worn components, which helps minimize downtime and reduces overall operational costs.

Wide Industrial Applications:

The exceptional performance of this gear rack makes it a versatile solution across numerous fields including industrial automation, CNC machining centers, robotics, and logistics systems. It facilitates precise robotic arm movements on automated production lines, ensures micron-level displacement accuracy in CNC tools, and plays a critical role in conveyor and mobile robotic systems, supporting the advancement toward high-end manufacturing.

Choose Yuchen DIN6 V-Guide Ground Helical Gear Rack for unmatched quality, reliable performance, and comprehensive technical support. With professional expertise and advanced technology, Yuchen is committed to providing precise, stable, and efficient transmission solutions, partnering with you to shape the future of industrial innovation.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español