Ground Gear

2M DIN6 Ground Helical Flange Gear

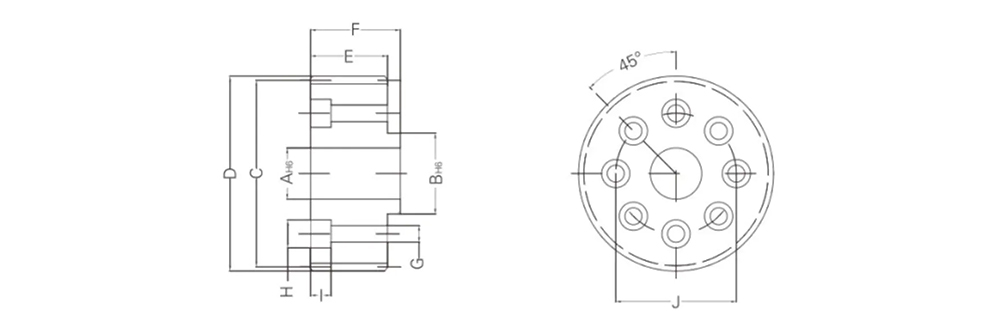

Specifications

Precision Grade: DIN 6

Material: 20CrMnTi

Type: Helical Rack

Left hand angle: 19°31'42"

Hardness Treatment: Overall carburizing, HRC55–60

Manufacturing Process: Gear grinding

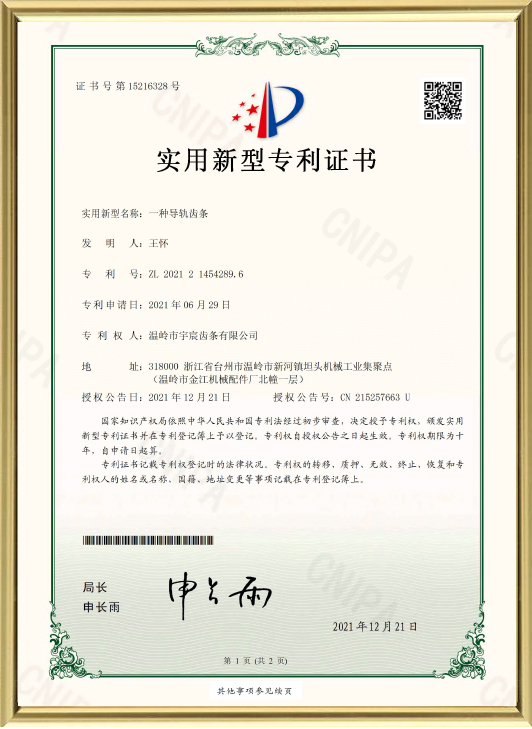

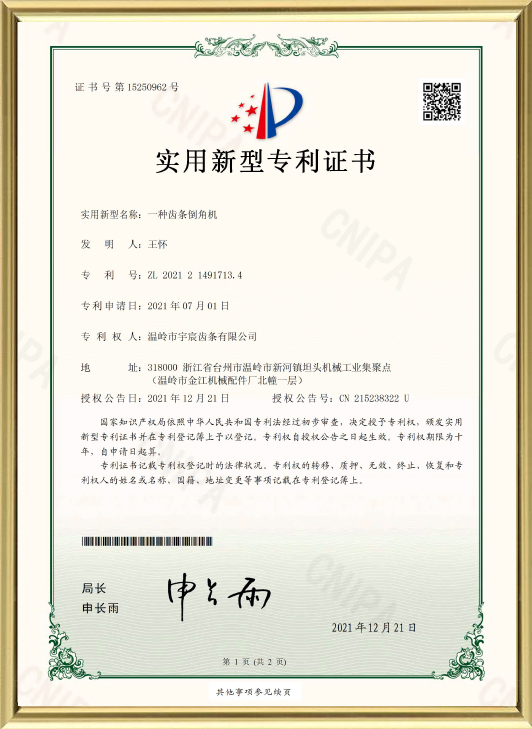

In the industrial sector, gears serve as critical components in transmission systems, where their performance directly impacts equipment efficiency and operational stability. The Yuzhen 2M Ground Helical Flange Gear stands out among similar products due to its exceptional quality and exquisite craftsmanship, making it an ideal choice for industrial transmission applications.

1. Premium Material Selection Lays the Foundation for Quality

The Yuzhen 2M Ground Helical Flange Gear is manufactured from high-quality 20CrMnTi alloy steel. This material offers nice comprehensive mechanical properties that, after heat treatment, significantly enhance hardness and wear resistance. It provides good strength and toughness, particularly suited for heavy load and impact conditions. By selecting this material at the source, the gear ensures outstanding durability and reliability, maintaining stable operation over extended periods even under harsh working environments, thereby reducing maintenance frequency and replacement costs.

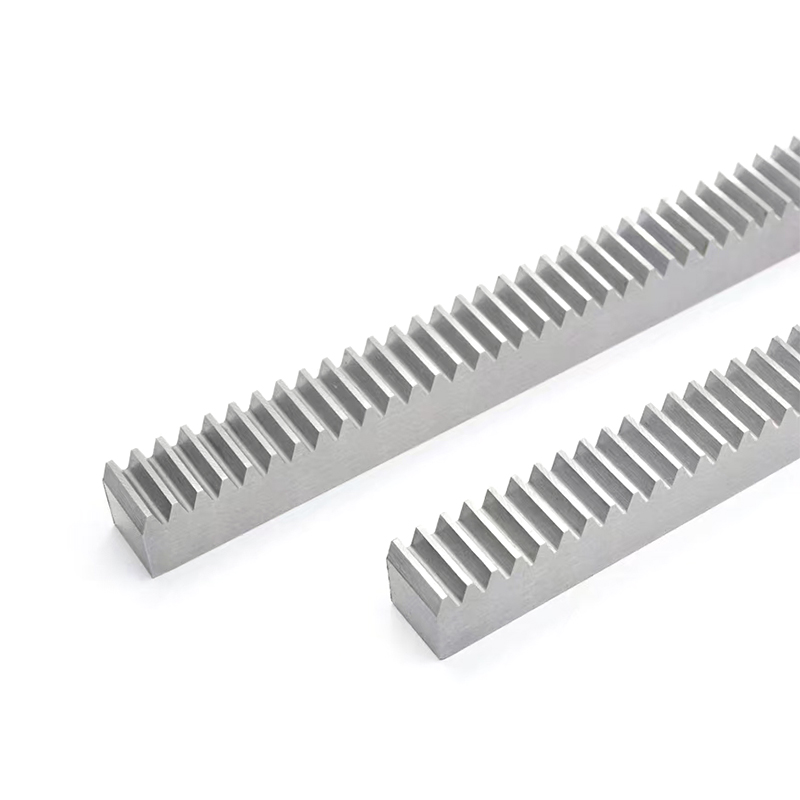

2. Grinding Process Ensures High Precision and Quality

High precision is the core advantage of the Yuzhen 2M Ground Helical Flange Gear. During manufacturing, advanced grinding techniques are applied to finely finish the gear tooth surfaces. The ground teeth achieve a low surface roughness and accuracy reaching DIN6 grade or higher. This precision enables tighter and smoother tooth meshing during operation, substantially reducing noise and vibration in the transmission process. It also enhances transmission efficiency and guarantees precise motion control, fulfilling the stringent accuracy requirements of applications such as CNC machine tools and precision automation equipment.

3. Unique Design to Meet Diverse Requirements

Flange Structure: The distinctive flange design facilitates easier and more secure installation. With the flange plate, the gear can be directly connected to the equipment shaft or other components, minimizing the need for additional mounting accessories and complex installation steps. This not only improves installation efficiency but also strengthens the connection reliability, effectively preventing transmission failures caused by loosening and ensuring stable equipment operation.

2M Module: The 2-module size is carefully engineered and market-validated, balancing sufficient transmission torque with compact gear dimensions and weight. This module size suits a wide range of transmission systems with varying power and speed demands, offering strong versatility. It is widely applicable in industrial automation production lines, robotics, logistics equipment, and more.

4. Wide Application Supports Industrial Upgrading

Thanks to its outstanding performance, the Yuzhen 2M Ground Helical Flange Gear supports precise positioning and efficient gripping in industrial robotic arms; guarantees accurate tool path control in CNC machine tools for high-precision part machining; provides stable power for flexible motion in robotic joint transmission systems; and ensures smooth, efficient material handling in logistics conveyor and sorting systems.

Choosing the Yuzhen 2M Ground Helical Flange Gear means opting for a high-quality, high-precision, and highly reliable transmission solution. With a professional attitude and advanced technology, Yuzhen offers solid transmission support for your industrial equipment, working together to create a brilliant future in the industrial field.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español