Ground Gear

1.5M DIN6 Ground Helical Gear

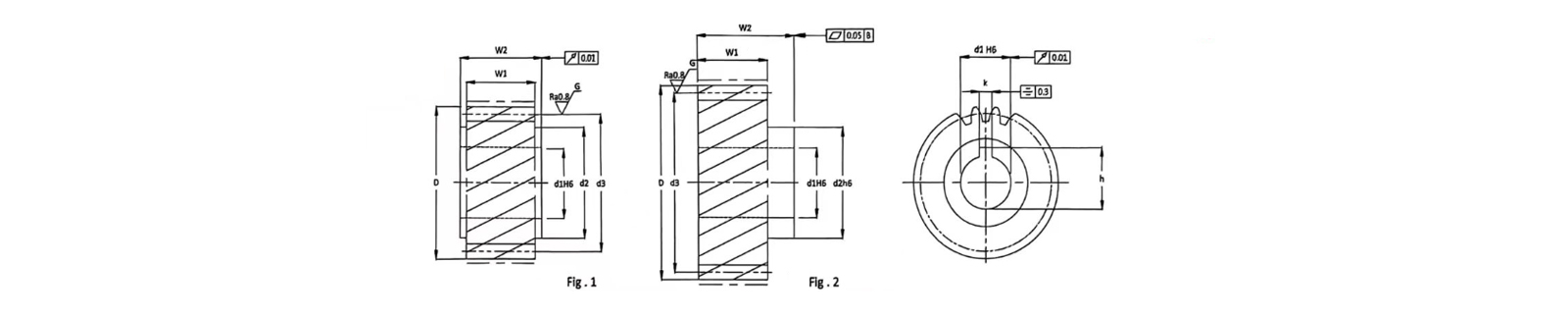

Specifications

Precision Grade: DIN 6

Material: 20CrMnTi

Type: Helical Rack

Left hand angle: 19°31'42"

Hardness Treatment: Overall carburizing, HRC55–60

Manufacturing Process: Gear grinding

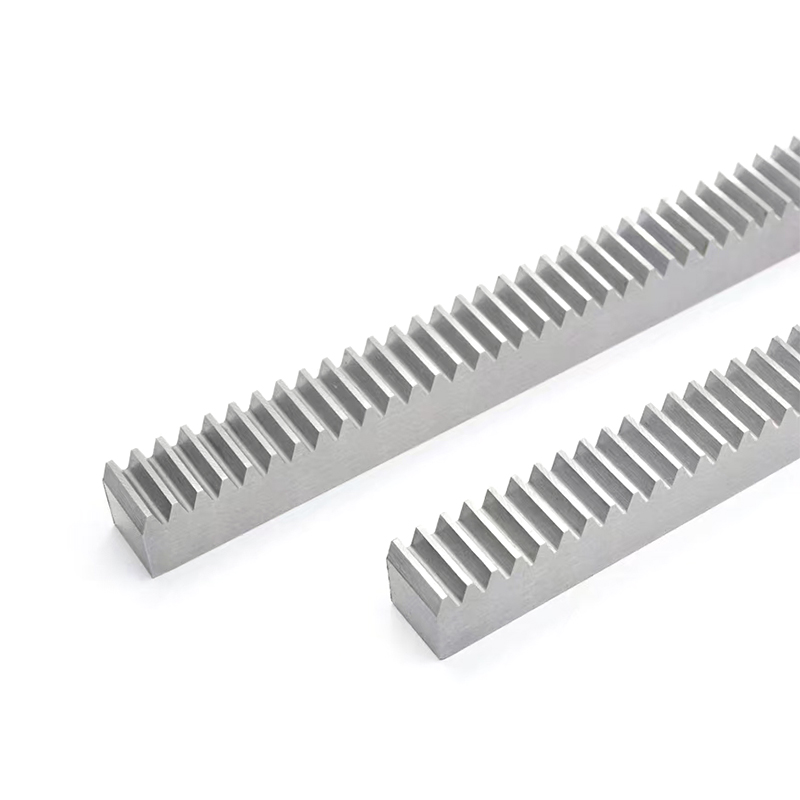

This 1.5M DIN6 Ground Helical Gear is manufactured using an advanced gear grinding process, delivering exceptional accuracy in both tooth profile and pitch. With deviations controlled within a very narrow range, each gear mesh achieves consistent precision and stability. Such performance is crucial for applications requiring exact transmission ratios, such as precision instruments and high-end machine tools. In optical equipment, for example, this gear ensures precise lens movement and positioning, directly contributing to good imaging quality.

Quiet Operation for Noise-Sensitive Environments

The finely ground gear surface minimizes impact and friction during meshing, significantly reducing operating noise and vibration. This silent operation makes ground helical gears ideal for environments with strict noise control requirements, such as medical devices and office automation systems. In hospitals, for instance, these gears ensure that diagnostic equipment runs quietly without disturbing patients or medical staff.

High Wear Resistance for Extended Equipment Lifespan

The grinding process enhances surface density, increasing the hardness and wear resistance of the gear. When operating under heavy loads and long duty cycles, ground helical gears experience significantly less wear than conventionally machined gears. This results in longer maintenance intervals and overall equipment longevity, premierly reducing operational costs. In heavy-duty machinery and construction equipment, these gears withstand harsh environments and demanding workloads, maintaining reliable performance over time.

Broad Compatibility for Diverse Industrial Applications

Whether applied to spur gears, helical gears, or worm gears, gear grinding technology significantly improves overall performance. Ground helical gears are widely used across aerospace, automotive manufacturing, robotics, and automated production systems. In aircraft engines, they help ensure stable and efficient operation, supporting flight safety. In automotive transmissions, they enable smooth gear shifts, improving driving comfort and control.

With their exceptional precision, quiet operation, high wear resistance, and broad adaptability, ground helical gears are an integral component in modern industrial systems, driving the advancement of high-performance and high-precision engineering.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español