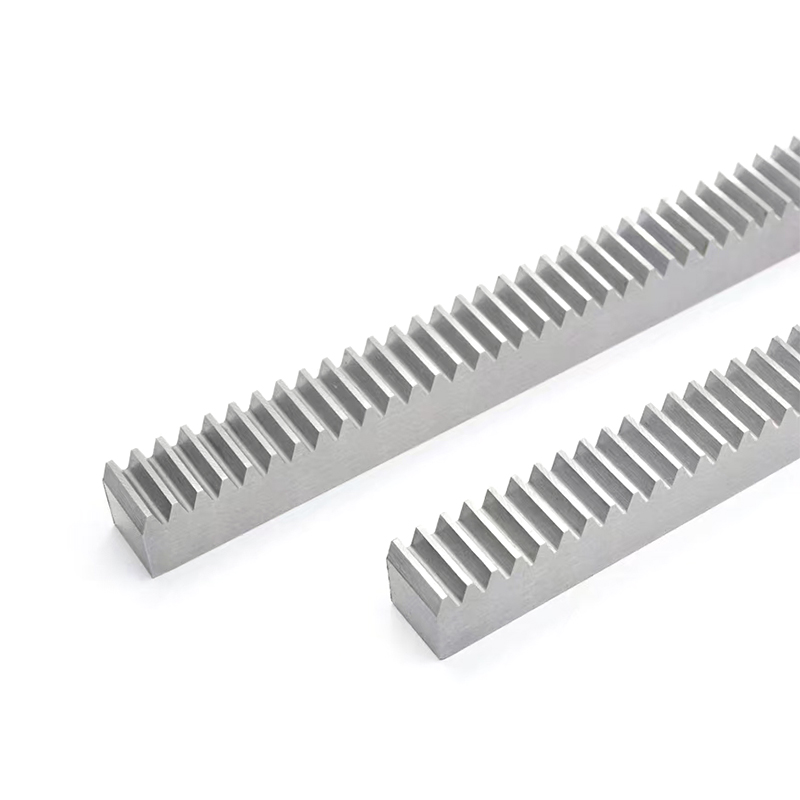

Ground Gear

2M DIN6 Ground Helical Gear

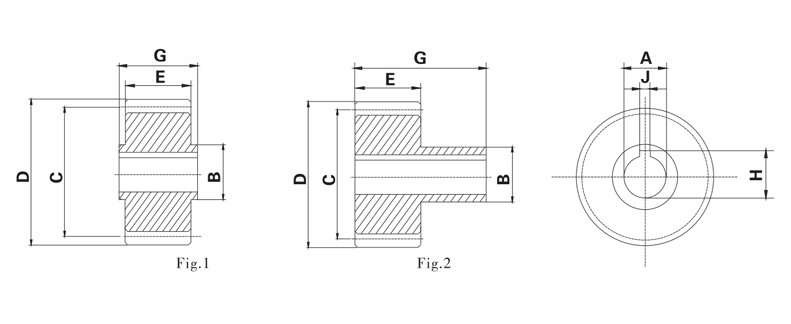

Specifications

Precision Grade: DIN 6

Material: 20CrMnTi

Type: Helical Rack

Left hand angle: 19°31'42"

Hardness Treatment: Overall carburizing, HRC55–60

Manufacturing Process: Gear grinding

In industrial systems, gears are fundamental components that directly impact the efficiency and reliability of mechanical operation. YUCHEN ground gears are engineered with precision, manufactured with care, and built to meet the demanding standards of modern industry.

1. Premium Materials for Long-Term Reliability

YUCHEN's helical gears are manufactured using high-quality 20CrMnTi or SCM440 alloy steel. These materials offer an nice balance of strength, wear resistance, and toughness after heat treatment, making them suitable for a wide range of industrial transmission applications. The mechanical properties of these alloys ensure stable performance even under high loads, shock, and high-speed rotation—significantly reducing equipment maintenance frequency and operational costs.

2. Advanced Processes Ensure Dimensional Accuracy

Hot Forging & Preform Rolling: High-density forged blanks are created through hot die forging and wedge cross-rolling, improving structural integrity and reducing machining allowances.

Isothermal Normalizing: Controlled heat treatment prepares the microstructure for nice machinability and reduces deformation during final hardening.

CNC Turning: All blanks are machined on CNC lathes in a single setup, achieving high perpendicularity and consistency across batches.

Gear Hobbing and Shaping: High-speed hobbing and shaping machines are used for internal and external gear cutting, enhanced by tool coating technology to improve tool life and productivity.

Gear Shaving: Radial gear shaving refines the tooth profile and lead, achieving good precision and surface finish—especially suited for mass production.

Carburizing and Quenching: YUCHEN applies advanced carburizing and quenching techniques to enhance surface hardness and internal strength while minimizing residual stresses.

Precision Grinding: Post-heat-treatment grinding of bores, faces, and outer diameters ensures tight tolerances and smooth operation.

Rigorous Inspection: Each gear undergoes multiple quality checks using high-precision measuring equipment to ensure dimensional accuracy, profile integrity, and surface finish compliance.

3. Distinctive Features for Demanding Applications

High Precision: Achieving DIN 6 accuracy or better, with less pitch and profile deviation, making them ideal for CNC machines, automation systems, and other high-precision environments.

Low Noise: Accurate tooth geometry and ground finishes ensure quiet meshing and smooth transmission, suitable for noise-sensitive equipment such as medical devices and laboratory automation.

High Hardness & Wear Resistance: The advanced carburizing process delivers a hardened tooth surface that resists wear even under continuous high-load and high-speed conditions.

Exceptional Stability: Consistent quality and optimized design allow stable performance, reducing the risk of failures and enabling continuous operation across a wide range of industries.

4. Versatile Applications Across Industrial Sectors

Industrial Automation: Integral to robotic joints and conveyor systems, enabling precise motion control and stable performance on automated production lines.

CNC Machine Tools: Critical for tool feed and worktable drive systems, enhancing the accuracy of parts manufacturing in industries such as aerospace and automotive.

Robotics: Used in joint actuation systems for industrial and service robots, delivering reliable motion control in complex environments.

Energy Sector: Deployed in power generation equipment, including wind, hydro, thermal, and nuclear plants, where high torque transmission and consistent performance are essential.

Medical Equipment: Ideal for precision devices like surgical instruments and dental chairs, combining corrosion resistance, low noise, and smooth operation for enhanced patient comfort and equipment reliability.

Choosing YUCHEN ground helical gears means selecting precision, reliability, and durability in power transmission. With expert craftsmanship and cutting-edge technology, YUCHEN supports your industrial systems with high-performance gear solutions—partnering with you to drive innovation and excellence in modern manufacturing.

+86-13306862930 / +86-18668881826

+86-13306862930 / +86-18668881826

English

English 中文简体

中文简体 русский

русский Español

Español